Understanding Radio Frequency Inductors

I. Introduction

In the realm of electronics, components work together to create complex systems that power our modern world. Among these components, the radio frequency inductor (RF inductor) plays a crucial role in various applications, particularly in communication technologies. This article aims to demystify RF inductors, exploring their definition, significance, design, applications, and future trends.

II. Basics of Inductors

A. What is an Inductor?

An inductor is a passive electronic component that stores energy in a magnetic field when electrical current flows through it. The fundamental function of an inductor is to resist changes in current, making it essential for various applications in electronic circuits.

1. Definition and Function

Inductors are often used in filters, oscillators, and energy storage applications. They work on the principle of electromagnetic induction, where a changing current creates a magnetic field that induces a voltage in the opposite direction.

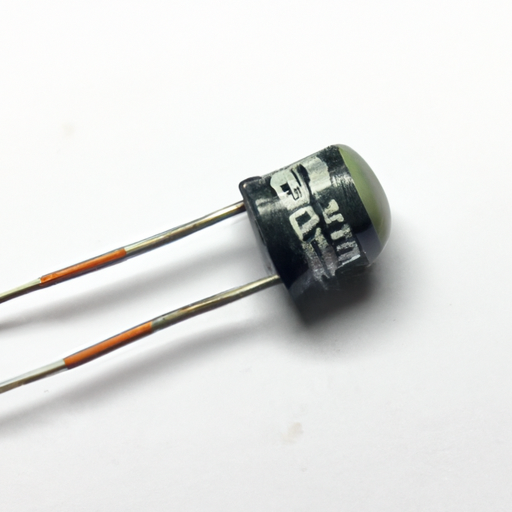

2. Basic Components and Construction

Typically, an inductor consists of a coil of wire wound around a core material. The core can be made of air, iron, or ferrite, which influences the inductor's performance characteristics.

B. Inductance and Its Measurement

1. Definition of Inductance

Inductance is the property of an inductor that quantifies its ability to store energy in a magnetic field. It is defined as the ratio of the induced voltage to the rate of change of current.

2. Units of Measurement (Henries)

Inductance is measured in henries (H), with common subunits including millihenries (mH) and microhenries (µH). The higher the inductance, the more energy the inductor can store.

C. Types of Inductors

Inductors can be categorized based on their core materials:

1. Air-Core Inductors

These inductors use air as the core material, offering low inductance values and high-frequency performance. They are often used in RF applications.

2. Iron-Core Inductors

Iron-core inductors provide higher inductance values and are used in applications requiring significant energy storage.

3. Ferrite-Core Inductors

Ferrite-core inductors combine the benefits of air and iron cores, offering high inductance with low losses at high frequencies.

III. Radio Frequency (RF) Overview

A. Definition of Radio Frequency

Radio frequency refers to the range of electromagnetic frequencies typically used for transmitting data wirelessly. This range spans from 3 kHz to 300 GHz, encompassing various applications, including radio, television, and mobile communications.

B. RF Spectrum and Its Applications

The RF spectrum is divided into several bands, each with specific applications. For instance, VHF (Very High Frequency) is used for FM radio, while UHF (Ultra High Frequency) is utilized for television broadcasts and mobile communications.

C. Importance of RF in Modern Technology

RF technology is integral to modern communication systems, enabling wireless connectivity, broadcasting, and data transmission. As technology advances, the demand for efficient RF components, including inductors, continues to grow.

IV. What is a Radio Frequency Inductor?

A. Definition and Characteristics

A radio frequency inductor is a specialized inductor designed to operate efficiently at high frequencies. These inductors are characterized by their low parasitic capacitance and high Q factor, making them suitable for RF applications.

B. Differences Between Standard Inductors and RF Inductors

While standard inductors can be used in various applications, RF inductors are optimized for performance at high frequencies. They are designed to minimize losses and maintain stability in RF circuits.

C. Applications of RF Inductors in Circuits

RF inductors are commonly used in RF filters, amplifiers, oscillators, and matching networks, playing a vital role in ensuring signal integrity and performance.

V. Design and Construction of RF Inductors

A. Materials Used in RF Inductors

1. Core Materials

The choice of core material significantly impacts the performance of RF inductors. Ferrite cores are often preferred for their high magnetic permeability and low losses at high frequencies.

2. Wire Types and Insulation

The wire used in RF inductors is typically made of copper or aluminum, with insulation materials selected to minimize losses and ensure durability.

B. Design Considerations

1. Size and Shape

The physical dimensions of RF inductors are critical for their performance. Smaller inductors are often preferred for compact designs, but size must be balanced with inductance requirements.

2. Q Factor and Self-Resonance

The Q factor measures the efficiency of an inductor, with higher values indicating lower losses. Self-resonance occurs when the inductance and parasitic capacitance resonate, limiting the inductor's effective frequency range.

C. Manufacturing Processes

RF inductors are manufactured using precision techniques to ensure consistency and performance. Advanced methods, such as automated winding and encapsulation, are employed to produce high-quality components.

VI. Applications of RF Inductors

A. RF Filters

RF inductors are essential in designing filters that allow specific frequency ranges to pass while blocking others, ensuring signal clarity in communication systems.

B. RF Amplifiers

In RF amplifiers, inductors help boost signal strength, enabling effective transmission and reception of data.

C. Oscillators and Mixers

RF inductors are used in oscillators to generate stable frequencies and in mixers to combine signals for modulation and demodulation.

D. Antenna Matching Networks

Inductors play a crucial role in matching the impedance of antennas to transmit and receive signals efficiently.

E. Power Amplifiers

In power amplifiers, RF inductors help manage power levels and improve overall efficiency in transmitting signals.

VII. Performance Characteristics of RF Inductors

A. Quality Factor (Q)

The Q factor is a critical performance metric for RF inductors, indicating their efficiency. A higher Q factor means lower energy losses, making the inductor more effective in RF applications.

B. Self-Resonant Frequency (SRF)

The self-resonant frequency is the frequency at which the inductor's inductance and parasitic capacitance resonate, leading to a significant drop in impedance. Understanding SRF is essential for designing circuits that operate within the desired frequency range.

C. Inductance Tolerance

Inductance tolerance refers to the allowable variation in inductance values. High-quality RF inductors typically have tighter tolerances to ensure consistent performance.

D. Temperature Stability

Temperature stability is crucial for RF inductors, as changes in temperature can affect inductance and performance. Selecting materials with low temperature coefficients helps maintain stability.

VIII. Challenges and Limitations

A. Parasitic Capacitance

Parasitic capacitance can limit the performance of RF inductors, especially at high frequencies. Designers must account for this when selecting and placing inductors in circuits.

B. Skin Effect and Proximity Effect

At high frequencies, the skin effect causes current to flow primarily on the surface of the conductor, leading to increased resistance. The proximity effect further complicates this by affecting nearby conductors. These effects must be considered in the design of RF inductors.

C. Thermal Management

RF inductors can generate heat during operation, necessitating effective thermal management strategies to prevent performance degradation.

IX. Future Trends in RF Inductor Technology

A. Advances in Materials and Manufacturing

Ongoing research into new materials and manufacturing techniques aims to enhance the performance and efficiency of RF inductors, enabling them to meet the demands of modern applications.

B. Miniaturization and Integration with Other Components

As electronic devices become smaller and more complex, the trend toward miniaturization and integration of RF inductors with other components is expected to continue, leading to more compact and efficient designs.

C. Emerging Applications in 5G and IoT

The rise of 5G technology and the Internet of Things (IoT) presents new opportunities for RF inductors. These technologies require high-performance components to support increased data rates and connectivity.

X. Conclusion

Radio frequency inductors are vital components in modern electronics, enabling efficient communication and signal processing. Understanding their design, applications, and performance characteristics is essential for anyone involved in electronics. As technology continues to evolve, RF inductors will play an increasingly important role in shaping the future of wireless communication and connectivity.

XI. References

For further reading and exploration of radio frequency inductors, consider the following resources:

1. "Inductors and Transformers for Power Electronics" by R. Jacob Baker

2. "RF Circuit Design" by Christopher Bowick

3. IEEE Standards for RF Components

4. Manufacturer datasheets for specific RF inductor products

By delving deeper into these resources, readers can gain a more comprehensive understanding of RF inductors and their significance in the ever-evolving landscape of electronics.

What are the Popular Models of Inductors in Shenzhen?

I. Introduction

Inductors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. As passive components, they store energy in a magnetic field when electrical current flows through them, making them essential in various applications, from power supplies to radio frequency circuits. Shenzhen, often dubbed the "Silicon Valley of Hardware," stands as a global hub for electronics manufacturing, housing numerous companies that design and produce a wide array of electronic components, including inductors. This article aims to explore the popular inductor models in Shenzhen, shedding light on their specifications, applications, and the broader market dynamics.

II. Understanding Inductors

A. Definition and Basic Principles of Inductors

An inductor is a passive electronic component that resists changes in electric current. It consists of a coil of wire, often wound around a core material, which can be air, iron, or ferrite. When current flows through the coil, a magnetic field is generated, and energy is stored in this field. The inductor's ability to store energy and oppose changes in current makes it vital in various electronic applications.

B. Types of Inductors

1. **Air-core Inductors**: These inductors do not use a magnetic core, relying solely on the coil of wire to create a magnetic field. They are typically used in high-frequency applications due to their low losses.

2. **Iron-core Inductors**: These inductors use an iron core to enhance the magnetic field, allowing for higher inductance values in a smaller size. They are commonly used in power applications.

3. **Ferrite-core Inductors**: Ferrite cores are made from a ceramic material that is magnetically conductive. These inductors are popular in high-frequency applications due to their low core losses.

4. **Toroidal Inductors**: Shaped like a doughnut, toroidal inductors provide a compact design with minimal electromagnetic interference. They are widely used in power supplies and audio applications.

C. Key Specifications and Parameters

1. **Inductance Value**: Measured in henries (H), this value indicates the inductor's ability to store energy. Higher inductance values are typically used in power applications.

2. **Current Rating**: This specification indicates the maximum current the inductor can handle without overheating or saturating.

3. **DC Resistance**: The resistance of the inductor when a direct current flows through it. Lower resistance is preferred to minimize energy loss.

4. **Saturation Current**: The current level at which the inductor can no longer store energy effectively, leading to a drop in inductance.

III. The Role of Shenzhen in the Inductor Market

A. Overview of Shenzhen's Electronics Ecosystem

Shenzhen's electronics ecosystem is characterized by a dense network of manufacturers, suppliers, and innovators. The city is home to numerous factories and research institutions, making it a vital center for the production of electronic components, including inductors. The rapid pace of technological advancement and the availability of skilled labor contribute to Shenzhen's prominence in the global electronics market.

B. Major Manufacturers and Suppliers of Inductors in Shenzhen

Several key players dominate the inductor market in Shenzhen. Companies like **Taiyo Yuden**, **Würth Elektronik**, and **Laird Technologies** have established a strong presence, offering a wide range of inductor models tailored to various applications. These manufacturers leverage advanced manufacturing techniques and materials to produce high-quality inductors that meet international standards.

C. The Impact of Local Regulations and Standards on Inductor Production

Shenzhen's regulatory environment plays a significant role in shaping the inductor market. Compliance with international standards, such as RoHS and REACH, ensures that manufacturers produce environmentally friendly products. Additionally, local regulations promote innovation and quality control, fostering a competitive landscape that benefits both manufacturers and consumers.

IV. Popular Inductor Models in Shenzhen

A. Overview of Leading Inductor Models

In Shenzhen, several inductor models have gained popularity due to their performance, reliability, and versatility. This section will delve into specific models that stand out in the market.

B. Detailed Analysis of Specific Models

1. **Model A: Taiyo Yuden LQH32CN**

- **Specifications**: Inductance value of 10 µH, current rating of 1.5 A, and a DC resistance of 0.1 ohms.

- **Applications**: Widely used in power supply circuits and DC-DC converters.

- **Market Demand**: High demand due to its compact size and efficiency in energy storage.

2. **Model B: Würth Elektronik WE-PD**

- **Specifications**: Inductance value of 22 µH, current rating of 2.5 A, and a DC resistance of 0.05 ohms.

- **Applications**: Commonly found in automotive electronics and industrial applications.

- **Market Demand**: Increasing demand driven by the automotive industry's shift towards electrification.

3. **Model C: Laird Technologies 1008CS**

- **Specifications**: Inductance value of 47 µH, current rating of 1.2 A, and a DC resistance of 0.2 ohms.

- **Applications**: Used in RF applications and signal processing.

- **Market Demand**: Steady demand due to its reliability in high-frequency applications.

4. **Model D: Coilcraft 0603CS**

- **Specifications**: Inductance value of 1 µH, current rating of 3 A, and a DC resistance of 0.03 ohms.

- **Applications**: Ideal for power management and filtering in compact devices.

- **Market Demand**: High demand in consumer electronics due to its small footprint.

C. Comparison of Features and Performance Among Popular Models

When comparing these models, several factors come into play, including inductance value, current rating, and application suitability. For instance, while Model A excels in compact power supply applications, Model B is better suited for automotive uses due to its higher current rating. Understanding these differences helps manufacturers and designers select the right inductor for their specific needs.

V. Applications of Inductors in Shenzhen

A. Common Applications in Consumer Electronics

Inductors are ubiquitous in consumer electronics, found in devices such as smartphones, tablets, and laptops. They are used in power management circuits, filtering applications, and signal processing, ensuring efficient operation and performance.

B. Use in Telecommunications and Networking Equipment

In telecommunications, inductors play a vital role in signal integrity and power supply stability. They are used in routers, switches, and base stations to manage power distribution and filter out noise, ensuring reliable communication.

C. Role in Automotive Electronics

The automotive industry increasingly relies on inductors for various applications, including electric vehicle power management, battery charging systems, and infotainment systems. As vehicles become more electrified, the demand for high-performance inductors continues to grow.

D. Inductors in Industrial Applications

In industrial settings, inductors are used in motor drives, power supplies, and automation systems. Their ability to handle high currents and provide stable performance makes them essential for efficient industrial operations.

VI. Trends and Innovations in Inductor Technology

A. Advances in Materials and Manufacturing Processes

Recent advancements in materials, such as the development of high-permeability ferrites and composite materials, have led to improved inductor performance. These innovations enhance efficiency, reduce losses, and enable the production of smaller inductors.

B. Miniaturization and Its Impact on Inductor Design

The trend towards miniaturization in electronics has driven the design of smaller inductors without compromising performance. Manufacturers are increasingly focusing on creating compact inductors that meet the demands of modern devices.

C. The Rise of Custom Inductors and Their Significance in the Market

As applications become more specialized, the demand for custom inductors has risen. Manufacturers are now offering tailored solutions to meet specific requirements, allowing for greater flexibility and performance optimization in various applications.

VII. Challenges in the Inductor Market

A. Supply Chain Issues and Their Effects on Availability

The global supply chain has faced significant disruptions, impacting the availability of raw materials and components. These challenges have led to increased lead times and costs for manufacturers, affecting the overall inductor market.

B. Competition Among Manufacturers

The inductor market in Shenzhen is highly competitive, with numerous manufacturers vying for market share. This competition drives innovation but can also lead to price wars, impacting profitability for some companies.

C. Environmental Regulations and Sustainability Concerns

As environmental regulations become more stringent, manufacturers must adapt to comply with sustainability standards. This shift requires investment in eco-friendly materials and processes, which can pose challenges for some companies.

VIII. Conclusion

In summary, inductors are essential components in modern electronics, with a wide range of applications across various industries. Shenzhen's role as a manufacturing hub has fostered the development of popular inductor models that meet the demands of the global market. As technology continues to evolve, the future of inductor models in Shenzhen looks promising, with ongoing innovations and trends shaping the landscape. Understanding the significance of inductors and their applications is crucial for anyone involved in electronics design and manufacturing.

IX. References

- Taiyo Yuden. (n.d.). Product Catalog. Retrieved from [Taiyo Yuden Website]

- Würth Elektronik. (n.d.). Inductor Product Line. Retrieved from [Würth Elektronik Website]

- Laird Technologies. (n.d.). Inductor Solutions. Retrieved from [Laird Technologies Website]

- Coilcraft. (n.d.). Inductor Specifications. Retrieved from [Coilcraft Website]

- Industry Reports on Inductor Market Trends and Innovations.

What are the 10 Mainstream Inductor Design Models?

Introduction

Inductors are fundamental components in electrical circuits, playing a crucial role in energy storage, filtering, and signal processing. They store energy in a magnetic field when electrical current flows through them, making them essential in various applications, from power supplies to radio frequency (RF) circuits. The design of inductors is critical, as it directly influences their performance, efficiency, and suitability for specific applications. This article explores ten mainstream inductor design models, providing insights into their characteristics, applications, and significance in the field of electrical engineering.

1. Basic Inductor Model

The basic inductor model represents an ideal inductor, characterized by its inductance, current, and voltage. In this model, the inductor is assumed to have no resistance or losses, meaning it can store energy indefinitely without dissipating it. The relationship between voltage (V), current (I), and inductance (L) is described by the formula:

\[ V = L \frac{dI}{dt} \]

This model is primarily used in circuit analysis to simplify calculations and understand the fundamental behavior of inductors. While it is an oversimplification, it serves as a foundation for more complex models that account for real-world factors.

2. Series Resistance Model

In reality, inductors exhibit series resistance, known as equivalent series resistance (ESR). This resistance arises from the wire used to wind the inductor and the resistance of the core material. The presence of ESR impacts the performance and efficiency of the inductor, leading to power losses in the form of heat.

The series resistance model is particularly relevant in power electronics and RF circuits, where efficiency is paramount. Designers must consider ESR when selecting inductors for applications such as DC-DC converters, where minimizing losses can significantly enhance overall system performance.

3. Parallel Resistance Model

The parallel resistance model introduces the concept of equivalent parallel resistance (EPR), which accounts for energy losses due to leakage currents in the inductor. This model is essential for understanding the quality factor (Q) of the inductor, which is a measure of its efficiency. A higher Q indicates lower energy losses and better performance.

In high-frequency applications, such as RF amplifiers and oscillators, the parallel resistance model becomes crucial. Designers must carefully select inductors with appropriate Q values to ensure stable and efficient operation in these demanding environments.

4. Core Loss Model

The core material used in an inductor significantly influences its performance, particularly in terms of core losses. Core losses can be categorized into hysteresis losses and eddy current losses. Hysteresis losses occur due to the magnetization and demagnetization of the core material, while eddy current losses arise from circulating currents induced within the core.

Understanding core losses is vital in transformer and inductor design, as they can lead to significant energy dissipation. Designers must choose core materials that minimize these losses while meeting the inductance and current handling requirements of the application.

5. Saturation Model

Magnetic saturation is a critical phenomenon in inductors that occurs when the magnetic core reaches its maximum flux density. Beyond this point, any increase in current does not result in a proportional increase in inductance, leading to a decrease in the inductor's effectiveness.

The saturation model is essential for applications in power supply circuits and converters, where inductors are subjected to varying current levels. Designers must ensure that inductors are selected with appropriate saturation ratings to prevent performance degradation and potential circuit failure.

6. Temperature Coefficient Model

Temperature can significantly affect the inductance of an inductor. The temperature coefficient model describes how inductance changes with temperature variations. This is particularly important in applications where inductors are exposed to fluctuating temperatures, such as in automotive and aerospace industries.

Designers often implement temperature compensation techniques to mitigate the effects of temperature on inductance. This ensures that the inductor maintains its performance characteristics across a wide temperature range, enhancing reliability and functionality in critical applications.

7. Parasitic Capacitance Model

Parasitic capacitance is an unintended capacitance that exists between the windings of an inductor and between the inductor and its surroundings. This capacitance can adversely affect the high-frequency performance and stability of the inductor, leading to unwanted resonances and signal distortion.

The parasitic capacitance model is crucial for high-frequency applications, where inductors are used in filters and oscillators. Designers must consider the effects of parasitic capacitance and implement design strategies to minimize its impact, ensuring optimal performance in demanding environments.

8. Nonlinear Inductor Model

Inductors can exhibit nonlinear behavior, where inductance varies with the applied current. This nonlinearity can be influenced by factors such as core material properties and the geometry of the inductor. The nonlinear inductor model is essential for accurately predicting the behavior of inductors in RF and microwave circuits, where precise control of inductance is critical.

Designers must account for nonlinear characteristics when selecting inductors for applications that require high precision and stability, ensuring that the inductor performs as expected under varying operating conditions.

9. Multi-Layer Inductor Model

Multi-layer inductors are designed with multiple layers of winding, allowing for increased inductance in a compact form factor. This design approach offers several benefits, including reduced size, improved performance, and enhanced thermal management.

The multi-layer inductor model is particularly advantageous in compact electronic devices, such as smartphones and wearables, where space is at a premium. Designers can leverage multi-layer inductors to achieve higher inductance values without compromising on size or performance.

10. Integrated Inductor Model

Integrated inductors are a key innovation in semiconductor technology, allowing inductors to be fabricated directly onto silicon chips. This integration offers several advantages, including reduced size, improved performance, and lower manufacturing costs.

However, the design of integrated inductors presents unique challenges, such as limited space and the need to optimize for various performance parameters. As technology advances, integrated inductors are expected to play an increasingly important role in the development of compact and efficient electronic devices.

Conclusion

In conclusion, understanding the various inductor design models is essential for engineers and designers working in the field of electrical engineering. Each model offers unique insights into the behavior and performance of inductors, allowing for informed decisions when selecting components for specific applications. As technology continues to evolve, advancements in inductor design will play a crucial role in shaping the future of electronic devices, enabling greater efficiency, performance, and miniaturization.

References

1. Hsieh, "Inductor Design for Power Electronics," IEEE Transactions on Power Electronics, vol. 30, no. 5, pp. 2345-2356, 2015.

2. R. W. Erickson and D. Maksimovic, "Fundamentals of Power Electronics," 2nd ed. Springer, 2001.

3. M. H. Rashid, "Power Electronics: Circuits, Devices, and Applications," 4th ed. Pearson, 2014.

4. J. G. Webster, "The Measurement, Instrumentation, and Sensors Handbook," CRC Press, 1999.

5. "Inductor Design Guide," Texas Instruments, [Online]. Available: https://www.ti.com/lit/an/slyt123/slyt123.pdf.

This blog post provides a comprehensive overview of the ten mainstream inductor design models, highlighting their characteristics, applications, and significance in electrical engineering. By understanding these models, designers can make informed decisions that enhance the performance and efficiency of their circuits.

Important Patents Related to the Role of Inductors in Circuits

I. Introduction

Inductors are passive electrical components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electrical circuits, serving functions such as filtering, energy storage, and voltage regulation. The significance of inductors extends across multiple industries, including consumer electronics, telecommunications, automotive, and renewable energy. As technology advances, the importance of patents in the development of inductor technology cannot be overstated. Patents protect innovations, encourage research and development, and ultimately drive the industry forward.

II. Historical Context of Inductor Technology

The journey of inductor technology began in the early 19th century with the discovery of electromagnetic induction by Michael Faraday. This foundational principle paved the way for the development of inductors. Over the years, various inventors and engineers have contributed to the evolution of inductor design and function.

Key patents have played a significant role in shaping inductor technology. For instance, early patents focused on inductor design and materials, leading to the creation of more efficient and compact inductors. Innovations in manufacturing processes, such as the introduction of automated winding techniques, have also been pivotal in enhancing the performance and reliability of inductors.

III. Types of Inductors and Their Applications

Inductors come in various types, each suited for specific applications.

A. Air-core Inductors

Air-core inductors are simple coils of wire without a magnetic core. They are commonly used in radio frequency applications due to their low losses and high-frequency performance.

B. Iron-core Inductors

Iron-core inductors utilize a ferromagnetic core to increase inductance. They are widely used in power supplies and transformers, where higher inductance values are required.

C. Ferrite-core Inductors

Ferrite-core inductors are made from ferrite materials, which provide high magnetic permeability and low losses at high frequencies. They are commonly found in switching power supplies and RF applications.

D. Specialty Inductors

Specialty inductors, such as toroidal inductors and multilayer inductors, are designed for specific applications. Toroidal inductors, with their doughnut-shaped cores, minimize electromagnetic interference, making them ideal for sensitive electronic devices. Multilayer inductors, on the other hand, are compact and suitable for surface-mount technology.

E. Applications in Different Industries

Inductors are integral to various industries. In consumer electronics, they are used in power supplies, audio equipment, and signal processing. In telecommunications, inductors play a vital role in filters and amplifiers. The automotive industry relies on inductors for power management and electric vehicle systems. Additionally, renewable energy systems, such as solar inverters and wind turbines, utilize inductors for efficient energy conversion.

IV. Key Patents in Inductor Technology

Several significant patents have shaped the landscape of inductor technology.

A. Overview of Significant Patents

1. **Patent for Improved Inductor Design**: This patent introduced a novel design that enhanced the efficiency and performance of inductors, allowing for better energy storage and reduced losses.

2. **Patent for High-Frequency Inductors**: This innovation focused on materials and geometries that improved the performance of inductors at high frequencies, making them suitable for modern communication systems.

3. **Patent for Miniaturized Inductors**: As electronic devices became smaller, the demand for compact inductors grew. This patent addressed the challenge of miniaturization while maintaining performance, leading to the development of smaller, more efficient inductors.

B. Analysis of the Impact of These Patents on the Industry

The impact of these patents on the industry has been profound. Technological advancements resulting from these innovations have led to more efficient and reliable inductors, enabling the development of advanced electronic devices. Market implications include increased competition among manufacturers and the emergence of new applications for inductors in various sectors.

V. Innovations in Inductor Technology

Recent advancements in materials and design have opened new avenues for inductor technology.

A. Recent Advancements in Materials and Design

1. **Use of Nanomaterials**: The incorporation of nanomaterials in inductor design has led to improved performance characteristics, such as higher inductance values and reduced losses.

2. **3D Printing in Inductor Manufacturing**: 3D printing technology has revolutionized the manufacturing process of inductors, allowing for complex geometries and customized designs that were previously unattainable.

B. Patents Related to Innovative Inductor Technologies

1. **Wireless Power Transfer Inductors**: As wireless charging technology gains popularity, patents related to inductors designed for efficient wireless power transfer have emerged, enabling the development of new charging solutions.

2. **Inductors for Energy Harvesting Applications**: Innovations in inductors for energy harvesting applications, such as those used in wearable devices and IoT sensors, have led to the creation of self-sustaining systems that reduce reliance on traditional power sources.

VI. Challenges and Future Directions

Despite the advancements in inductor technology, several challenges remain.

A. Current Challenges in Inductor Technology

1. **Size and Efficiency Constraints**: As electronic devices continue to shrink, the demand for smaller and more efficient inductors increases. Balancing size with performance remains a significant challenge.

2. **Thermal Management Issues**: Inductors generate heat during operation, and managing this heat is crucial for maintaining performance and reliability. Innovative cooling solutions are needed to address this issue.

B. Future Trends and Potential Patentable Innovations

1. **Smart Inductors and IoT Applications**: The rise of the Internet of Things (IoT) presents opportunities for the development of smart inductors that can communicate and adapt to changing conditions, enhancing the functionality of connected devices.

2. **Sustainable Materials and Manufacturing Processes**: As sustainability becomes a priority, there is a growing interest in developing inductors using eco-friendly materials and manufacturing processes, which could lead to new patentable innovations.

VII. Conclusion

In conclusion, inductors play a vital role in electrical circuits, and the patents related to their technology have significantly influenced the industry. From historical developments to recent innovations, the evolution of inductor technology continues to shape various sectors. As we look to the future, ongoing research and innovation in inductor technology will be essential for addressing current challenges and unlocking new possibilities. The call to action for continued exploration in this field is clear, as the advancements in inductor technology will undoubtedly have far-reaching implications for the future of electronics.

VIII. References

A comprehensive list of patents, scholarly articles, and additional resources for further reading on inductors and their applications would be included here to support the information presented in the blog post.