Market Policies for Capacitor Films: An In-Depth Analysis

I. Introduction

Capacitor films are essential components in a wide range of electronic devices, serving as dielectric materials that store and release electrical energy. These films are crucial in applications such as power electronics, automotive systems, and renewable energy technologies. As the demand for electronic devices continues to rise, understanding the market policies that govern capacitor films becomes increasingly important. This blog post will explore the various market policies affecting capacitor films, including market dynamics, regulatory frameworks, trade policies, pricing strategies, sustainability initiatives, and future trends.

II. Market Overview

A. Global Demand for Capacitor Films

The global demand for capacitor films is driven by several key industries, including consumer electronics, automotive, telecommunications, and renewable energy. The rapid growth of electric vehicles (EVs) and the increasing adoption of renewable energy sources, such as solar and wind power, have significantly boosted the demand for high-performance capacitor films.

1. Key Industries Utilizing Capacitor Films

Consumer Electronics: Capacitor films are widely used in smartphones, laptops, and other electronic devices, where they play a critical role in power management and signal processing.

Automotive: The automotive industry increasingly relies on capacitor films for applications such as electric power steering, braking systems, and energy storage in hybrid and electric vehicles.

Telecommunications: Capacitor films are essential in telecommunications equipment, ensuring stable power supply and signal integrity.

Renewable Energy: Capacitor films are used in inverters and energy storage systems, facilitating the integration of renewable energy sources into the grid.

2. Trends in the Electronics Market

The electronics market is witnessing a shift towards miniaturization and increased efficiency, driving the demand for advanced capacitor films. Innovations in materials and manufacturing processes are enabling the development of thinner, lighter, and more efficient capacitor films, which are essential for modern electronic applications.

B. Major Players in the Capacitor Film Market

The capacitor film market is characterized by the presence of several leading manufacturers, including:

1. Leading Manufacturers

Mitsubishi Electric: A key player in the capacitor film market, known for its high-quality polyester and polypropylene films.

Toray Industries: Specializes in advanced polymer films used in capacitors, with a strong focus on research and development.

3M: Offers a wide range of capacitor films, including specialty films for high-performance applications.

2. Market Share Analysis

The market share of these manufacturers is influenced by factors such as product quality, technological advancements, and customer relationships. As competition intensifies, companies are increasingly focusing on innovation and sustainability to maintain their market positions.

III. Regulatory Framework

A. Overview of Regulations Affecting Capacitor Films

The capacitor film market is subject to various regulations that ensure product safety, environmental protection, and compliance with industry standards.

1. Environmental Regulations

Governments worldwide are implementing stringent environmental regulations to reduce the impact of manufacturing processes on the environment. These regulations often require manufacturers to adopt eco-friendly materials and production methods.

2. Safety Standards

Safety standards, such as those set by the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), govern the performance and reliability of capacitor films. Compliance with these standards is essential for manufacturers to ensure product safety and gain market acceptance.

B. Impact of Regulations on Manufacturing Processes

1. Compliance Costs

Adhering to regulatory requirements can lead to increased compliance costs for manufacturers. These costs may include investments in new technologies, employee training, and certification processes.

2. Innovation and Technology Adaptation

While compliance costs can be burdensome, they also drive innovation. Manufacturers are compelled to invest in research and development to create more efficient and environmentally friendly capacitor films, ultimately benefiting the industry as a whole.

IV. Trade Policies

A. Tariffs and Import/Export Regulations

Trade policies play a significant role in shaping the capacitor film market. Tariffs and import/export regulations can impact pricing and availability, influencing manufacturers' decisions regarding sourcing and distribution.

1. Impact on Pricing and Availability

High tariffs on imported raw materials can lead to increased production costs, which may be passed on to consumers. Conversely, favorable trade agreements can enhance market access and reduce costs for manufacturers.

2. Trade Agreements Affecting the Capacitor Film Market

Trade agreements, such as the United States-Mexico-Canada Agreement (USMCA) and the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP), can facilitate trade in capacitor films by reducing tariffs and promoting collaboration among member countries.

B. Regional Trade Policies

1. North America

In North America, trade policies are influenced by the need to balance domestic manufacturing with international competition. The region is home to several leading capacitor film manufacturers, and policies that support local production can enhance the market's competitiveness.

2. Europe

European trade policies emphasize sustainability and environmental protection, which can impact the capacitor film market. Manufacturers are encouraged to adopt eco-friendly practices to comply with regulations and meet consumer expectations.

3. Asia-Pacific

The Asia-Pacific region is a significant player in the capacitor film market, with countries like China, Japan, and South Korea leading in production and consumption. Trade policies in this region are evolving to address issues such as intellectual property rights and environmental standards.

V. Market Entry Strategies

A. Strategies for New Entrants

New entrants in the capacitor film market must adopt effective strategies to establish their presence and compete with established players.

1. Joint Ventures and Partnerships

Collaborating with existing manufacturers through joint ventures or partnerships can provide new entrants with access to established distribution networks, technology, and market knowledge.

2. Licensing and Technology Transfer

Licensing agreements can enable new entrants to leverage existing technologies and intellectual property, reducing the time and investment required to develop new products.

B. Challenges Faced by New Entrants

1. Capital Investment

Entering the capacitor film market often requires significant capital investment in manufacturing facilities, research and development, and marketing efforts.

2. Market Competition

The capacitor film market is highly competitive, with established players holding significant market share. New entrants must differentiate their products and demonstrate value to gain market traction.

VI. Pricing Policies

A. Factors Influencing Pricing of Capacitor Films

Several factors influence the pricing of capacitor films, including raw material costs, production efficiency, and market demand.

1. Raw Material Costs

The prices of raw materials, such as polymers and additives, can fluctuate based on market conditions, impacting the overall pricing of capacitor films.

2. Production Efficiency

Manufacturers that invest in advanced production technologies can achieve greater efficiency, reducing costs and enabling competitive pricing.

B. Pricing Strategies Employed by Manufacturers

1. Cost-Plus Pricing

Many manufacturers adopt a cost-plus pricing strategy, where they calculate the total production costs and add a markup to determine the selling price.

2. Competitive Pricing

In a competitive market, manufacturers may employ competitive pricing strategies to attract customers and gain market share, often leading to price wars that can impact profitability.

VII. Sustainability and Environmental Policies

A. Growing Emphasis on Sustainable Practices

As environmental concerns continue to rise, the capacitor film market is witnessing a growing emphasis on sustainable practices.

1. Eco-Friendly Materials and Production Methods

Manufacturers are increasingly adopting eco-friendly materials and production methods to reduce their environmental footprint. This shift not only meets regulatory requirements but also aligns with consumer preferences for sustainable products.

2. Recycling and Waste Management

Implementing recycling programs and waste management practices is becoming a priority for manufacturers, contributing to a circular economy and reducing the environmental impact of capacitor film production.

B. Corporate Social Responsibility (CSR) Initiatives

1. Impact on Brand Reputation

Companies that prioritize sustainability and social responsibility can enhance their brand reputation, attracting environmentally conscious consumers and investors.

2. Consumer Preferences

As consumers become more aware of environmental issues, their preferences are shifting towards brands that demonstrate a commitment to sustainability. This trend is influencing manufacturers to adopt more responsible practices.

VIII. Future Trends and Predictions

A. Technological Advancements in Capacitor Films

The capacitor film market is poised for significant technological advancements, driven by the need for higher performance and efficiency.

1. Innovations in Materials and Design

Research and development efforts are focused on creating new materials and designs that enhance the performance of capacitor films, enabling their use in emerging applications such as electric vehicles and renewable energy systems.

2. Impact of Emerging Technologies

Emerging technologies, such as artificial intelligence and the Internet of Things (IoT), are expected to drive demand for advanced capacitor films that can support the growing complexity of electronic devices.

B. Anticipated Changes in Market Policies

1. Evolving Regulations

As environmental concerns continue to grow, regulations governing the capacitor film market are likely to evolve, requiring manufacturers to adopt more sustainable practices and materials.

2. Shifts in Trade Dynamics

Changes in global trade dynamics, influenced by geopolitical factors and economic conditions, may impact the capacitor film market, affecting pricing, availability, and competition.

IX. Conclusion

In conclusion, the market policies for capacitor films are shaped by a complex interplay of factors, including regulatory frameworks, trade policies, pricing strategies, and sustainability initiatives. Understanding these policies is crucial for stakeholders in the capacitor film market, as they navigate the challenges and opportunities presented by a rapidly evolving industry. As technological advancements continue to drive innovation, the future outlook for the capacitor film market remains promising, with significant potential for growth and development.

X. References

- Academic journals on materials science and electronics.

- Industry reports from market research firms.

- Government publications and regulations related to environmental standards and safety.

This comprehensive analysis of market policies for capacitor films provides valuable insights for manufacturers, investors, and industry stakeholders, highlighting the importance of adapting to changing market dynamics and consumer preferences.

What are the Product Characteristics of Capacitors?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in various applications ranging from power supply filtering to signal processing. These passive electronic devices store and release electrical energy, making them essential for the functionality of countless electronic devices. In this article, we will explore the product characteristics of capacitors, including their basic principles, key features, specialized characteristics, and applications.

II. Basic Principles of Capacitors

A. How Capacitors Work

At its core, a capacitor consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store electrical energy in the form of an electric charge. The amount of charge a capacitor can store is defined by its capacitance, which is measured in farads (F).

1. Charge Storage Mechanism

The charge storage mechanism of a capacitor is based on the principle of electrostatics. When a voltage is applied, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. The stored charge can be released when the circuit requires it, providing a temporary power source.

2. Capacitance and Its Units

Capacitance is the measure of a capacitor's ability to store charge per unit voltage. It is expressed in farads, with common subunits including microfarads (µF) and picofarads (pF). The higher the capacitance value, the more charge the capacitor can store.

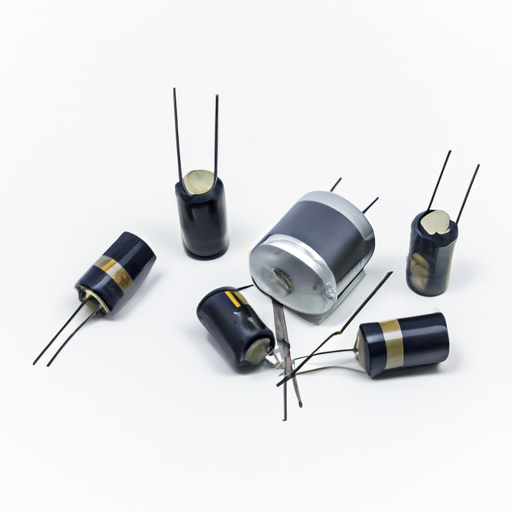

B. Types of Capacitors

Capacitors come in various types, each with unique characteristics suited for specific applications. The most common types include:

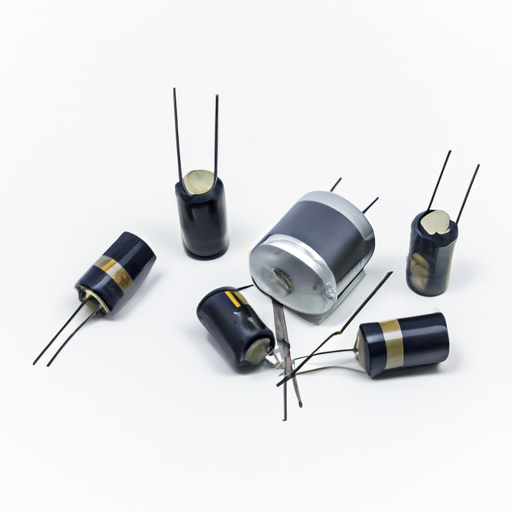

1. Electrolytic Capacitors

Electrolytic capacitors are polarized devices that offer high capacitance values in a compact size. They are commonly used in power supply circuits for filtering and smoothing voltage fluctuations.

2. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are widely used in high-frequency applications due to their low equivalent series resistance (ESR).

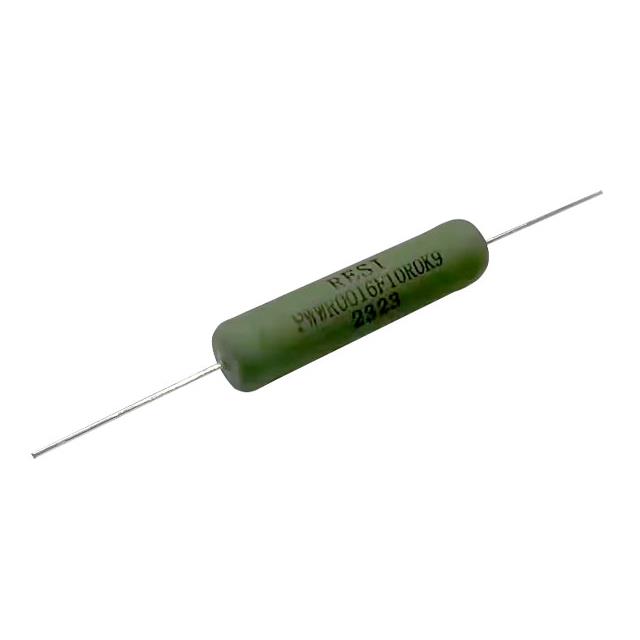

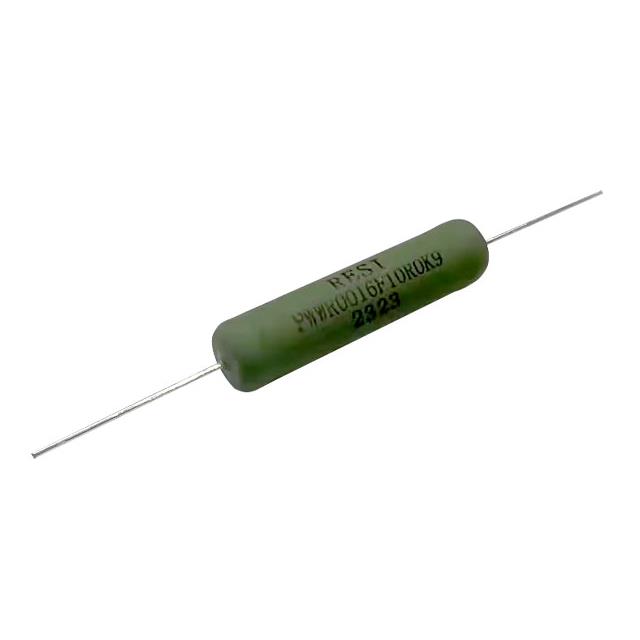

3. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their excellent stability, low ESR, and high voltage ratings, making them suitable for audio and high-frequency applications.

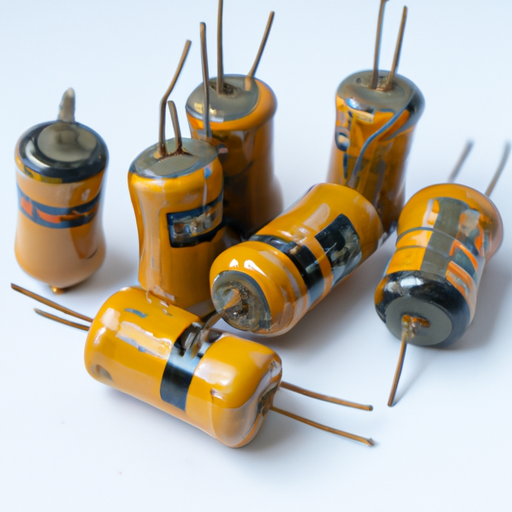

4. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance values and small size. They are often used in applications where space is limited, such as in mobile devices.

5. Supercapacitors

Supercapacitors, also known as ultracapacitors, have extremely high capacitance values and are used for energy storage applications. They can charge and discharge rapidly, making them ideal for applications requiring quick bursts of energy.

III. Key Product Characteristics of Capacitors

When selecting a capacitor for a specific application, several key characteristics must be considered.

A. Capacitance Value

1. Measurement and Units

Capacitance is measured in farads, with common values ranging from picofarads to microfarads. The choice of capacitance value depends on the specific requirements of the circuit.

2. Tolerance Levels

Capacitors come with specified tolerance levels, indicating how much the actual capacitance can vary from the stated value. Common tolerance levels include ±5%, ±10%, and ±20%. Selecting a capacitor with the appropriate tolerance is crucial for ensuring circuit performance.

B. Voltage Rating

1. Importance of Voltage Rating

The voltage rating of a capacitor indicates the maximum voltage it can withstand without breaking down. Exceeding this voltage can lead to capacitor failure, which may damage the circuit.

2. Derating Guidelines

To enhance reliability, it is recommended to operate capacitors at a voltage lower than their rated voltage, a practice known as derating. This helps to extend the lifespan of the capacitor and prevent premature failure.

C. Equivalent Series Resistance (ESR)

1. Definition and Importance

Equivalent series resistance (ESR) is the internal resistance of a capacitor that affects its performance, particularly in high-frequency applications. A lower ESR indicates better performance and efficiency.

2. Impact on Performance

High ESR can lead to power loss and heat generation, reducing the overall efficiency of the circuit. Therefore, selecting capacitors with low ESR is essential for applications requiring high-frequency operation.

D. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient of a capacitor indicates how its capacitance value changes with temperature. This characteristic is crucial for applications where temperature fluctuations are expected.

2. Types of Temperature Coefficients

Capacitors can have different temperature coefficients, such as C0G (Class 1) and X7R (Class 2). Class 1 capacitors offer better stability, while Class 2 capacitors provide higher capacitance values but with more variation in capacitance with temperature.

E. Lifetime and Reliability

1. Factors Affecting Lifetime

The lifetime of a capacitor is influenced by factors such as temperature, voltage, and ripple current. Operating a capacitor within its specified limits can significantly enhance its longevity.

2. Reliability Testing Standards

Capacitors are subjected to various reliability testing standards, such as MIL-PRF-39014 and IEC 60384, to ensure they meet industry requirements for performance and durability.

IV. Specialized Capacitor Characteristics

In addition to the key characteristics mentioned above, capacitors possess specialized features that can impact their performance in specific applications.

A. Frequency Response

1. Impedance and Reactance

The impedance of a capacitor varies with frequency, affecting its performance in AC circuits. Understanding the frequency response is essential for selecting capacitors for high-frequency applications.

2. Applications in High-Frequency Circuits

Capacitors with low ESR and appropriate capacitance values are critical in high-frequency circuits, such as RF amplifiers and oscillators, where signal integrity is paramount.

B. Leakage Current

1. Definition and Measurement

Leakage current refers to the small amount of current that flows through a capacitor even when it is not connected to a circuit. This characteristic is crucial for applications requiring low power consumption.

2. Impact on Circuit Performance

Excessive leakage current can lead to power loss and affect the performance of sensitive circuits. Therefore, selecting capacitors with low leakage current is essential for applications such as timing circuits and precision analog devices.

C. Self-Resonant Frequency

1. Explanation of Self-Resonance

Self-resonant frequency is the frequency at which a capacitor's reactance becomes zero, causing it to behave like a short circuit. This characteristic is important for understanding how capacitors will perform in AC applications.

2. Applications and Limitations

While self-resonance can be beneficial in certain applications, it can also limit the effective frequency range of a capacitor. Designers must consider this characteristic when selecting capacitors for specific frequency applications.

V. Applications of Capacitors

Capacitors are used in a wide range of applications, including:

A. Power Supply Filtering

Capacitors are commonly used in power supply circuits to filter out voltage fluctuations and provide a stable output voltage.

B. Signal Coupling and Decoupling

In audio and communication circuits, capacitors are used for coupling and decoupling signals, allowing for the transmission of AC signals while blocking DC components.

C. Timing Circuits

Capacitors play a crucial role in timing circuits, where they are used in conjunction with resistors to create time delays in electronic devices.

D. Energy Storage Solutions

Supercapacitors are increasingly used in energy storage applications, providing quick bursts of energy for devices such as electric vehicles and renewable energy systems.

E. Audio Applications

In audio circuits, capacitors are used for filtering and coupling signals, ensuring high-quality sound reproduction.

VI. Conclusion

In summary, capacitors are essential components in electronic circuits, with various product characteristics that influence their performance in different applications. Understanding these characteristics, including capacitance value, voltage rating, ESR, temperature coefficient, and specialized features, is crucial for selecting the right capacitor for a specific application. As technology continues to evolve, advancements in capacitor technology will likely lead to new applications and improved performance, making capacitors an exciting area of study for engineers and designers alike.

VII. References

A. Suggested Reading and Resources

1. "Capacitors: Technology and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

B. Industry Standards and Guidelines

1. MIL-PRF-39014: Military Specification for Capacitors

2. IEC 60384: International Standard for Fixed Capacitors for Use in Electronic Equipment

This comprehensive overview of the product characteristics of capacitors provides valuable insights for anyone involved in electronics design and engineering. Understanding these characteristics will help ensure the successful implementation of capacitors in various applications, ultimately leading to more reliable and efficient electronic devices.

What are the Advantages of Capacitors and Their Products?

I. Introduction

Capacitors are fundamental components in the world of electronics, playing a crucial role in various applications across multiple industries. Defined as passive electrical devices that store and release electrical energy, capacitors are essential for managing energy flow in circuits. Their importance in modern technology cannot be overstated, as they contribute to the functionality and efficiency of countless devices, from consumer electronics to renewable energy systems. This blog post will explore the advantages of capacitors and their products, highlighting their significance in today's technological landscape.

II. Basic Principles of Capacitors

A. Structure and Function of Capacitors

At their core, capacitors consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. The amount of energy a capacitor can store is determined by its capacitance, which is measured in farads (F).

B. Types of Capacitors

There are several types of capacitors, each with unique characteristics suited for specific applications. Common types include:

Ceramic Capacitors: Known for their small size and stability, ceramic capacitors are widely used in high-frequency applications.

Electrolytic Capacitors: These capacitors offer high capacitance values and are often used in power supply circuits.

Tantalum Capacitors: Known for their reliability and stability, tantalum capacitors are used in applications requiring compact size and high capacitance.

Film Capacitors: These capacitors are known for their low loss and high voltage ratings, making them suitable for audio and power applications.

C. How Capacitors Store and Release Energy

Capacitors store energy in the form of an electric field. When connected to a circuit, they can release this stored energy quickly, making them ideal for applications requiring rapid energy discharge. This ability to store and release energy efficiently is one of the key advantages of capacitors.

III. Advantages of Capacitors

A. Energy Storage

1. Quick Energy Release

One of the primary advantages of capacitors is their ability to release energy quickly. This characteristic is particularly beneficial in applications where rapid bursts of power are needed, such as in camera flashes or power amplifiers.

2. High Power Density

Capacitors can deliver a significant amount of power in a short time, making them suitable for applications that require high power density. This feature is essential in various electronic devices, including power tools and electric vehicles.

B. Voltage Regulation

1. Smoothing Voltage Fluctuations

Capacitors play a vital role in voltage regulation by smoothing out fluctuations in electrical supply. They can absorb excess voltage during peak loads and release it during low demand, ensuring a stable power supply.

2. Maintaining Stable Power Supply

In power supply circuits, capacitors help maintain a consistent voltage level, which is crucial for the proper functioning of electronic devices. This stability enhances the reliability and performance of the entire system.

C. Signal Filtering

1. Noise Reduction in Electronic Circuits

Capacitors are widely used in signal filtering applications to reduce noise in electronic circuits. By blocking high-frequency noise while allowing low-frequency signals to pass, capacitors enhance the overall performance of audio and communication systems.

2. Enhancing Signal Integrity

In digital circuits, capacitors help maintain signal integrity by preventing signal distortion. This capability is essential for high-speed data transmission and communication systems.

D. Size and Versatility

1. Compact Design Options

Capacitors come in various sizes and shapes, allowing for compact designs in electronic devices. This versatility enables engineers to create smaller, more efficient products without compromising performance.

2. Wide Range of Applications

Capacitors are used in a diverse array of applications, from consumer electronics to industrial machinery. Their adaptability makes them indispensable in modern technology.

E. Longevity and Reliability

1. Durability in Various Environments

Capacitors are designed to withstand a range of environmental conditions, including temperature fluctuations and humidity. This durability ensures their longevity and reliability in various applications.

2. Low Maintenance Requirements

Unlike some other electronic components, capacitors typically require minimal maintenance. This characteristic makes them a cost-effective choice for many applications, reducing the need for frequent replacements.

IV. Applications of Capacitors

A. Consumer Electronics

Capacitors are integral to consumer electronics, playing a crucial role in devices such as smartphones, tablets, and laptops. They help regulate power supply, filter signals, and enhance audio and video quality, contributing to a better user experience.

B. Industrial Applications

In industrial settings, capacitors are used in motors and drives to improve efficiency and performance. They also play a vital role in power factor correction, helping to optimize energy consumption and reduce costs.

C. Renewable Energy Systems

Capacitors are increasingly being integrated into renewable energy systems, such as solar inverters and wind energy systems. They help manage energy flow, improve efficiency, and enhance the overall performance of these systems.

D. Automotive Industry

In the automotive industry, capacitors are essential components in electric vehicles, where they store and release energy to support various functions. They are also used in advanced driver-assistance systems (ADAS) to enhance safety and performance.

V. Innovations and Future Trends

A. Advancements in Capacitor Technology

The field of capacitor technology is continually evolving, with significant advancements being made in recent years. The development of supercapacitors, which offer higher energy storage capacity and faster charging times, is a notable innovation. Emerging materials and designs are also being explored to enhance the performance and efficiency of capacitors.

B. Impact of Capacitors on Energy Efficiency

Capacitors play a crucial role in improving energy efficiency, particularly in smart grids and sustainable technologies. By optimizing energy flow and reducing waste, capacitors contribute to a more sustainable future.

VI. Conclusion

In summary, capacitors offer numerous advantages that make them essential components in modern technology. Their ability to store and release energy quickly, regulate voltage, filter signals, and provide compact design options are just a few of the reasons they are widely used across various industries. As technology continues to advance, the significance of capacitors will only grow, paving the way for innovative applications and improved energy efficiency. Understanding the advantages of capacitors and their products is crucial for anyone interested in the future of technology and electronics.

VII. References

For further exploration of capacitors and their products, consider the following resources:

1. "Capacitors: Principles and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Online courses on electronics and capacitor technology from platforms like Coursera and edX.

By delving deeper into these resources, readers can gain a more comprehensive understanding of capacitors and their vital role in modern technology.

Important Product Categories of Capacitors

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are passive electrical devices that store energy in an electric field, allowing them to release that energy when needed. The importance of capacitors cannot be overstated, as they are integral to the functioning of a wide range of electronic devices, from simple household appliances to complex industrial machinery. This article will explore the various product categories of capacitors, their characteristics, applications, and emerging trends in capacitor technology.

II. Basic Principles of Capacitors

A. How Capacitors Work

Capacitors operate on the principle of charge storage. When a voltage is applied across the terminals of a capacitor, an electric field is created, allowing the capacitor to store electrical energy. The amount of charge a capacitor can store is defined by its capacitance, measured in farads (F). The relationship between capacitance (C), voltage (V), and charge (Q) is given by the formula:

\[ Q = C \times V \]

B. Types of Capacitors Based on Construction

Capacitors can be categorized based on their construction and materials. The most common types include:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors use an electrolyte to achieve a larger surface area for charge storage.

2. **Ceramic Capacitors**: These capacitors use ceramic materials as the dielectric and are known for their stability and reliability.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their low losses and high insulation resistance.

4. **Tantalum Capacitors**: These are a type of electrolytic capacitor that uses tantalum as the anode material, offering high capacitance in a small package.

5. **Supercapacitors**: Also known as ultracapacitors, these devices can store a large amount of energy and are used in applications requiring rapid charge and discharge cycles.

III. Major Product Categories of Capacitors

A. Ceramic Capacitors

1. Characteristics and Applications

Ceramic capacitors are widely used in electronic circuits due to their small size, reliability, and stability over a range of temperatures and voltages. They are commonly found in applications such as decoupling, filtering, and timing circuits.

2. Types of Ceramic Capacitors

Class 1 (Temperature Stable): These capacitors have a stable capacitance over a wide temperature range and are used in precision applications.

Class 2 (High Capacitance): These capacitors offer higher capacitance values but have a more significant variation in capacitance with temperature and voltage.

B. Electrolytic Capacitors

1. Characteristics and Applications

Electrolytic capacitors are known for their high capacitance values, making them ideal for applications such as power supply filtering, energy storage, and coupling/decoupling in audio circuits.

2. Types of Electrolytic Capacitors

Aluminum Electrolytic Capacitors: These are the most common type, offering high capacitance and voltage ratings.

Tantalum Electrolytic Capacitors: These capacitors provide higher reliability and stability but are more expensive than aluminum electrolytics.

C. Film Capacitors

1. Characteristics and Applications

Film capacitors are known for their low dielectric losses and high insulation resistance. They are commonly used in applications such as audio equipment, power electronics, and timing circuits.

2. Types of Film Capacitors

Polyester Film Capacitors: These are widely used due to their cost-effectiveness and decent performance.

Polypropylene Film Capacitors: Known for their superior performance in high-frequency applications, these capacitors are often used in audio and RF circuits.

D. Tantalum Capacitors

1. Characteristics and Applications

Tantalum capacitors are known for their high capacitance in a small size, making them suitable for applications in mobile devices, computers, and automotive electronics.

2. Advantages and Disadvantages

While tantalum capacitors offer excellent performance, they can be more expensive and have a risk of failure if subjected to overvoltage conditions.

E. Supercapacitors

1. Characteristics and Applications

Supercapacitors can store a significant amount of energy and are used in applications requiring rapid charge and discharge cycles, such as energy harvesting, backup power supplies, and electric vehicles.

2. Comparison with Traditional Capacitors

Unlike traditional capacitors, supercapacitors can achieve much higher capacitance values, but they typically operate at lower voltages and have a shorter lifespan.

IV. Specialized Capacitor Types

A. Power Capacitors

1. Characteristics and Applications

Power capacitors are designed to improve the power factor in electrical systems, helping to reduce energy losses and improve efficiency. They are commonly used in industrial applications and power distribution systems.

2. Role in Power Factor Correction

By providing reactive power, power capacitors help to balance the load in electrical systems, reducing the demand on generators and improving overall system efficiency.

B. RF Capacitors

1. Characteristics and Applications

RF capacitors are designed to operate at high frequencies and are used in radio frequency applications, including transmitters, receivers, and filters.

2. Importance in Radio Frequency Applications

These capacitors must have low losses and high stability to ensure signal integrity and performance in RF circuits.

C. Motor Run and Motor Start Capacitors

1. Characteristics and Applications

Motor run capacitors are used to improve the efficiency of electric motors, while motor start capacitors provide the necessary boost to start the motor.

2. Role in Electric Motors

These capacitors help to create a phase shift in the motor windings, allowing for smoother operation and improved performance.

V. Emerging Trends in Capacitor Technology

A. Miniaturization and High-Density Capacitors

As electronic devices become smaller and more compact, there is a growing demand for miniaturized capacitors that can deliver high performance in limited space. Advances in materials and manufacturing techniques are enabling the development of high-density capacitors that meet these requirements.

B. Environmentally Friendly Capacitors

With increasing awareness of environmental issues, manufacturers are focusing on developing capacitors that are more environmentally friendly. This includes using sustainable materials and reducing the environmental impact of production processes.

C. Advancements in Supercapacitor Technology

Research and development in supercapacitor technology are leading to improved energy density, faster charging times, and longer lifespans. These advancements are expanding the potential applications of supercapacitors in various fields, including renewable energy and electric vehicles.

VI. Conclusion

In summary, capacitors are essential components in modern electronics, with various product categories tailored to meet specific needs and applications. From ceramic and electrolytic capacitors to specialized types like power and RF capacitors, each category offers unique characteristics and benefits. As technology continues to evolve, emerging trends such as miniaturization, environmentally friendly designs, and advancements in supercapacitor technology will shape the future of capacitor development. Understanding these product categories and their applications is crucial for anyone involved in electronics, as capacitors play a vital role in the performance and efficiency of electronic devices.

VII. References

A. Suggested Reading

- "Capacitors: Technology and Applications" by John Smith

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

B. Industry Standards and Guidelines

- IEC 60384: Standards for fixed capacitors

- EIA-198: Standard for capacitors used in electronic equipment

C. Manufacturer Resources

- Manufacturer websites for detailed specifications and product catalogs

- Technical papers and white papers from capacitor manufacturers

This comprehensive overview of the important product categories of capacitors highlights their significance in electronic circuits and the ongoing advancements in capacitor technology. Understanding these components is essential for engineers, designers, and anyone involved in the electronics industry.