What is the Market Prospect of Wirewound Inductors?

I. Introduction

A. Definition of Wirewound Inductors

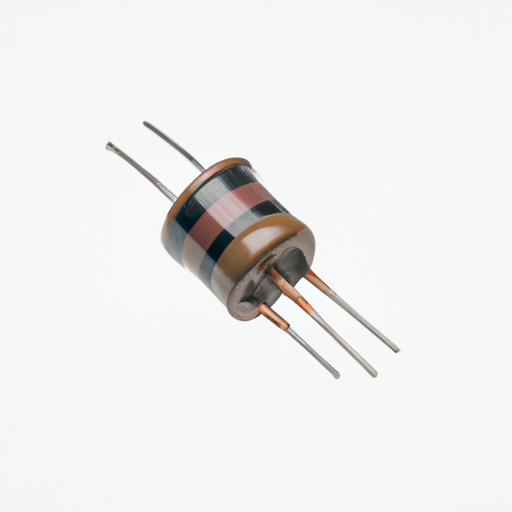

Wirewound inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are constructed by winding a conductive wire, typically copper, around a core material, which can be air, iron, or ferrite. The inductance value of these components is determined by the number of turns in the coil, the core material, and the geometry of the inductor.

B. Importance of Inductors in Electronic Circuits

Inductors play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. They are essential in applications ranging from power supplies to radio frequency circuits, where they help manage current and voltage levels, reduce noise, and improve overall circuit performance.

C. Overview of the Market Landscape

The market for wirewound inductors is experiencing significant growth, driven by the increasing demand for electronic devices across various sectors. As technology advances and industries evolve, the need for efficient and reliable inductors becomes more pronounced. This blog post will explore the market prospects of wirewound inductors, examining their types, applications, market drivers, challenges, regional analysis, and future trends.

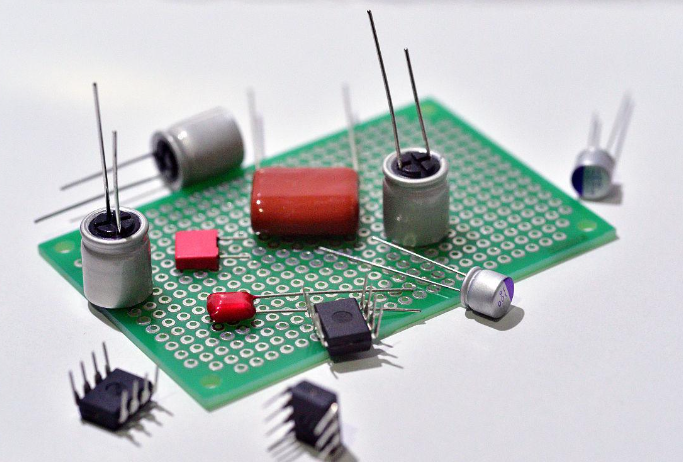

II. Types of Wirewound Inductors

A. Air-Core Inductors

Air-core inductors are constructed without a magnetic core, relying solely on the air surrounding the coil to provide inductance. They are typically used in high-frequency applications due to their low losses and high Q-factor, making them ideal for RF circuits.

B. Iron-Core Inductors

Iron-core inductors utilize an iron core to enhance inductance. The core material increases the magnetic permeability, allowing for a higher inductance value in a smaller physical size. These inductors are commonly used in power applications where efficiency is critical.

C. Ferrite-Core Inductors

Ferrite-core inductors use ferrite materials, which are ceramic compounds that exhibit magnetic properties. They are particularly effective at high frequencies and are widely used in applications such as switch-mode power supplies and telecommunications.

D. Comparison of Different Types

Each type of wirewound inductor has its advantages and disadvantages. Air-core inductors are lightweight and have low losses but are limited in inductance value. Iron-core inductors offer higher inductance but can suffer from saturation at high currents. Ferrite-core inductors provide a balance between size and performance, making them versatile for various applications.

III. Applications of Wirewound Inductors

A. Consumer Electronics

The consumer electronics sector is one of the largest markets for wirewound inductors. Devices such as smartphones, tablets, and laptops require inductors for power management, signal filtering, and noise reduction. As the demand for these devices continues to rise, so does the need for efficient inductors.

B. Automotive Industry

With the automotive industry undergoing a significant transformation towards electric and hybrid vehicles, wirewound inductors are becoming increasingly important. They are used in power converters, battery management systems, and electric motor drives, contributing to the overall efficiency and performance of modern vehicles.

C. Telecommunications

The expansion of telecommunications infrastructure, including 5G networks, is driving the demand for wirewound inductors. These components are essential in base stations, routers, and other communication devices, where they help manage power and signal integrity.

D. Industrial Equipment

Wirewound inductors are also widely used in industrial equipment, including motors, transformers, and power supplies. Their ability to handle high currents and voltages makes them suitable for various industrial applications, contributing to the efficiency and reliability of machinery.

E. Renewable Energy Systems

As the world shifts towards renewable energy sources, wirewound inductors are playing a vital role in systems such as solar inverters and wind turbines. They help manage power conversion and storage, ensuring the efficient operation of renewable energy systems.

IV. Market Drivers

A. Growing Demand for Consumer Electronics

The rapid growth of the consumer electronics market is a significant driver for wirewound inductors. As technology advances and consumers demand more sophisticated devices, the need for efficient inductors will continue to rise.

B. Advancements in Automotive Technology

The shift towards electric and autonomous vehicles is creating new opportunities for wirewound inductors. As automotive technology evolves, the demand for high-performance inductors will increase, driving market growth.

C. Expansion of Telecommunications Infrastructure

The rollout of 5G networks and the expansion of telecommunications infrastructure are boosting the demand for wirewound inductors. These components are essential for ensuring reliable communication and data transfer in modern networks.

D. Increasing Focus on Renewable Energy Solutions

The global push for renewable energy solutions is driving the demand for wirewound inductors in energy systems. As more countries invest in sustainable energy sources, the need for efficient power management components will grow.

V. Market Challenges

A. Competition from Alternative Technologies

Wirewound inductors face competition from alternative technologies, such as surface-mount inductors and integrated inductors. These alternatives may offer advantages in terms of size and cost, posing a challenge to traditional wirewound inductors.

B. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, affecting the availability of raw materials for wirewound inductors. Disruptions can lead to increased costs and delays in production, impacting market growth.

C. Cost Fluctuations of Raw Materials

The prices of raw materials used in wirewound inductors, such as copper and ferrite, can fluctuate significantly. These cost variations can affect profit margins and pricing strategies for manufacturers.

D. Regulatory Challenges

The electronics industry is subject to various regulations regarding environmental impact and safety standards. Compliance with these regulations can pose challenges for manufacturers of wirewound inductors, requiring investment in sustainable practices and materials.

VI. Regional Market Analysis

A. North America

North America is a significant market for wirewound inductors, driven by the presence of major electronics manufacturers and a strong demand for consumer electronics. The automotive sector's shift towards electric vehicles is also contributing to market growth in the region.

B. Europe

Europe is witnessing a growing demand for wirewound inductors, particularly in the automotive and renewable energy sectors. The region's focus on sustainability and innovation is driving advancements in inductor technology.

C. Asia-Pacific

The Asia-Pacific region is the largest market for wirewound inductors, fueled by the rapid growth of the electronics industry in countries like China, Japan, and South Korea. The increasing demand for consumer electronics and automotive applications is propelling market expansion.

D. Latin America

Latin America is emerging as a potential market for wirewound inductors, with growing investments in telecommunications and renewable energy. As the region develops its infrastructure, the demand for efficient inductors is expected to rise.

E. Middle East and Africa

The Middle East and Africa are witnessing increased investments in telecommunications and renewable energy projects, creating opportunities for wirewound inductors. As these markets develop, the demand for reliable electronic components will grow.

VII. Future Trends in Wirewound Inductors

A. Technological Innovations

The wirewound inductor market is expected to see continued technological innovations, including advancements in materials and manufacturing processes. These innovations will enhance performance and efficiency, meeting the evolving needs of various applications.

B. Miniaturization and Integration

As electronic devices become smaller and more compact, the trend towards miniaturization and integration of inductors into circuits will continue. Manufacturers will focus on developing smaller, more efficient wirewound inductors to meet these demands.

C. Sustainability and Eco-Friendly Materials

With increasing awareness of environmental issues, there is a growing emphasis on sustainability in the electronics industry. Manufacturers of wirewound inductors will likely explore eco-friendly materials and production methods to reduce their environmental impact.

D. Market Consolidation and Strategic Partnerships

The wirewound inductor market may experience consolidation as companies seek to enhance their competitive edge. Strategic partnerships and collaborations will be essential for companies to leverage resources and expertise in developing innovative products.

VIII. Conclusion

A. Summary of Market Prospects

The market prospects for wirewound inductors are promising, driven by the growing demand for consumer electronics, advancements in automotive technology, and the expansion of telecommunications infrastructure. Despite challenges such as competition from alternative technologies and supply chain disruptions, the overall outlook remains positive.

B. Final Thoughts on the Future of Wirewound Inductors

As technology continues to evolve, wirewound inductors will play a vital role in various applications, from consumer electronics to renewable energy systems. The industry must adapt to changing market dynamics and invest in innovation to remain competitive.

C. Call to Action for Stakeholders in the Industry

Stakeholders in the wirewound inductor industry, including manufacturers, suppliers, and researchers, should collaborate to address challenges and seize opportunities. By focusing on innovation, sustainability, and market expansion, they can contribute to the growth and success of this essential component in the electronics landscape.

IX. References

A. Academic Journals

- Journal of Applied Physics

- IEEE Transactions on Power Electronics

B. Industry Reports

- MarketsandMarkets: Inductor Market Report

- Grand View Research: Wirewound Inductor Market Analysis

C. Market Research Studies

- Research and Markets: Global Wirewound Inductor Market Trends

- Technavio: Wirewound Inductor Market Forecast

D. Relevant Websites and Articles

- Electronics Weekly

- EDN Network

This comprehensive analysis of the market prospects for wirewound inductors highlights their significance in the electronics industry and the factors influencing their growth. As technology advances, the demand for efficient and reliable inductors will continue to rise, presenting opportunities for innovation and development in this essential component.

Logic gates are the most basic components in digital circuits, used to perform logical operations. According to their functions and structures, logic gates can be divided into various types. In digital circuit design, commonly used logic gates include AND gates, OR gates, NOT gates, XOR gates, NAND gates, NOR gates, and more. Below are some popular logic gate models and their characteristics.1. 74LS00 (Quad 2-Input NAND Gate): The 74LS00 is a quad 2-input NAND gate with four input terminals and one output terminal. The output will be high only when all input terminals are high. This type of logic gate is commonly used for AND operations on multiple signals.2. 74LS08 (Quad 2-Input AND Gate): The 74LS08 is a quad 2-input AND gate similar to the 74LS00, but with a different output logic function. The output will be low if any input terminal is low. This type of logic gate is commonly used for NAND operations on multiple signals.3. 74LS32 (Quad 2-Input OR Gate): The 74LS32 is a quad 2-input OR gate with four input terminals and one output terminal. The output will be high if any input terminal is high. This type of logic gate is commonly used for OR operations on multiple signals.4. 74LS04 (Hex Inverter): The 74LS04 is a hex inverter with six input terminals and six output terminals. The logic relationship between input and output is inverted, meaning when the input is high, the output is low, and vice versa. This type of logic gate is commonly used for signal inversion.5. 74LS86 (Quad 2-Input XOR Gate): The 74LS86 is a quad 2-input XOR gate with four input terminals and one output terminal. The output will be high if an odd number of input ports are high, and low if an even number of input ports are high. This type of logic gate is commonly used for XOR operations on multiple signals.6. 74LS02 (Quad 2-Input NOR Gate): The 74LS02 is a quad 2-input NOR gate with four input terminals and one output terminal. The output will be low if all input terminals are high, and high if any input terminal is low. This type of logic gate is commonly used for NOR operations on multiple signals.7. 74LS32 (Quad 2-Input OR Gate): The 74LS32 is a quad 2-input OR gate with four input terminals and one output terminal. The output will be low if any input terminal is high, and high if all input terminals are low. This type of logic gate is commonly used for NOR operations on multiple signals.In conclusion, logic gates play a crucial role in digital circuit design, as different types of logic gates can perform different logical operations. Mastering the characteristics and uses of various logic gates is essential for digital circuit design and implementation. I hope this article has been helpful to readers. Thank you for reading!Logic gates are the most basic components in digital circuits, used to perform logical operations. According to their functions and structures, logic gates can be divided into various types. In digital circuit design, commonly used logic gates include AND gates, OR gates, NOT gates, XOR gates, NAND gates, NOR gates, and more. Below are some popular logic gate models and their characteristics.1. 74LS00 (Quad 2-Input NAND Gate): The 74LS00 is a quad 2-input NAND gate with four input terminals and one output terminal. The output will be high only when all input terminals are high. This type of logic gate is commonly used for AND operations on multiple signals.2. 74LS08 (Quad 2-Input AND Gate): The 74LS08 is a quad 2-input AND gate similar to the 74LS00, but with a different output logic function. The output will be low if any input terminal is low. This type of logic gate is commonly used for NAND operations on multiple signals.3. 74LS32 (Quad 2-Input OR Gate): The 74LS32 is a quad 2-input OR gate with four input terminals and one output terminal. The output will be high if any input terminal is high. This type of logic gate is commonly used for OR operations on multiple signals.4. 74LS04 (Hex Inverter): The 74LS04 is a hex inverter with six input terminals and six output terminals. The logic relationship between input and output is inverted, meaning when the input is high, the output is low, and vice versa. This type of logic gate is commonly used for signal inversion.5. 74LS86 (Quad 2-Input XOR Gate): The 74LS86 is a quad 2-input XOR gate with four input terminals and one output terminal. The output will be high if an odd number of input ports are high, and low if an even number of input ports are high. This type of logic gate is commonly used for XOR operations on multiple signals.6. 74LS02 (Quad 2-Input NOR Gate): The 74LS02 is a quad 2-input NOR gate with four input terminals and one output terminal. The output will be low if all input terminals are high, and high if any input terminal is low. This type of logic gate is commonly used for NOR operations on multiple signals.7. 74LS32 (Quad 2-Input OR Gate): The 74LS32 is a quad 2-input OR gate with four input terminals and one output terminal. The output will be low if any input terminal is high, and high if all input terminals are low. This type of logic gate is commonly used for NOR operations on multiple signals.In conclusion, logic gates play a crucial role in digital circuit design, as different types of logic gates can perform different logical operations. Mastering the characteristics and uses of various logic gates is essential for digital circuit design and implementation. I hope this article has been helpful to readers. Thank you for reading!

Common Production Processes of Chokes IntroductionA choke is an important inductive component widely used in electronic devices, especially in power management, filtering, and signal processing. Its main function is to suppress high-frequency noise, smooth current fluctuations, and improve the stability and reliability of the circuit. With the continuous development of electronic technology, the performance requirements of chokes are also increasing, making the optimization of production processes particularly important.In this article, we will delve into the basic structure of chokes, production process flow, key technologies, common issues, and future development trends, in order to provide reference for practitioners in related industries. Basic Structure of Chokes Selection of Magnetic Core MaterialsThe core part of a choke is the magnetic core, and the choice of material directly affects the performance of the choke. Common magnetic core materials include ferrites, silicon steel sheets, and powdered iron cores. Ferrite materials have good high-frequency characteristics and are suitable for high-frequency applications; while silicon steel sheets perform well in low-frequency applications. Powdered iron cores are increasingly favored for their excellent magnetic properties and low losses. Design of Winding CoilsWinding coils are another important component of chokes, and their design needs to consider factors such as the number of turns, wire diameter, and winding method. Increasing the number of turns can increase the inductance value, but it will also increase the DC resistance of the coil, affecting efficiency. Therefore, a reasonable balance is needed in the design. Role of Enclosure and Insulation MaterialsThe enclosure not only protects the internal structure of the choke but also prevents external interference. Insulation materials ensure electrical isolation between the coil and the magnetic core, preventing short circuits and leakage. Common insulation materials include polyester film, epoxy resin, etc. Production Process Flow of Chokes 1. Material Preparation Types and Characteristics of Magnetic Core MaterialsBefore producing chokes, various materials need to be prepared. The choice of magnetic core material is crucial, as the permeability, losses, and temperature characteristics of different materials will affect the performance of the final product. Selection of Winding Coil MaterialsWinding coils typically use copper or aluminum wire, with copper wire being widely used due to its excellent conductivity. The choice of wire diameter needs to be determined based on design requirements and current magnitude. Preparation of Insulation MaterialsThe choice of insulation materials is equally important to ensure their heat resistance, voltage resistance, and insulation performance to meet the requirements of different working environments. 2. Processing of Magnetic Cores Cutting and Forming of Magnetic CoresThe processing of magnetic cores typically involves cutting and forming. Precision in cutting is necessary to facilitate subsequent assembly. Forming needs to be done according to design requirements to ensure the shape of the magnetic core meets standards. Surface Treatment of Magnetic CoresSurface treatment can improve the corrosion resistance and mechanical strength of magnetic cores. Common treatment methods include spraying and galvanizing. Heat Treatment Process of Magnetic CoresHeat treatment can improve the magnetic properties of magnetic cores and reduce losses. The heat treatment process varies for different materials and needs to be adjusted accordingly. 3. Winding of Coils Selection of Winding EquipmentCoil winding is typically done using automated equipment to improve production efficiency and consistency. The choice of equipment needs to consider the specifications of the coil and the scale of production. Setting of Winding Process ParametersDuring the winding process, process parameters such as winding speed, tension, and number of turns need to be accurately set to ensure the quality of the coil. Insulation Treatment of CoilsAfter winding is completed, the coil needs to undergo insulation treatment. Common methods include impregnation and coating with insulation materials to improve its insulation performance. 4. Assembly of Components Bonding of Magnetic Cores and CoilsDuring assembly, the coil needs to be tightly bonded to the magnetic core to ensure good electromagnetic coupling. Care should be taken to avoid damaging the insulation layer of the coil during bonding. Addition of Insulation LayerAfter assembly, an additional insulation layer is usually added to further enhance the electrical isolation performance. Installation of EnclosureFinally, the enclosure is installed to protect the internal components, and the material and design of the enclosure need to consider factors such as heat dissipation and protection. 5. Testing and Inspection Electrical Performance TestingAfter assembly, chokes need to undergo electrical performance testing, including inductance value, DC resistance, and withstand voltage, to ensure they meet design requirements. Mechanical Strength TestingMechanical strength testing primarily evaluates the durability of chokes during use, ensuring they can withstand external impacts and vibrations. Environmental Adaptability TestingEnvironmental adaptability testing includes high temperature, low temperature, humidity, etc., to ensure the stability and reliability of chokes under various environmental conditions. Key Technologies in Production Processes Application of Automation Technology in ProductionWith the advancement of technology, automation technology has been widely applied in choke production. Automated equipment not only improves production efficiency but also reduces errors from manual operations, ensuring product consistency and stability. Quality Control and ManagementQuality control is crucial during the production process. By establishing a sound quality management system and implementing full monitoring, defect rates can be effectively reduced, and product qualification rates can be improved. Use of Environmentally Friendly Materials and Sustainable DevelopmentWith the increasing environmental awareness, more and more companies are paying attention to environmental issues in the production process. The use of environmentally friendly materials and sustainable production processes not only helps protect the environment but also enhances the company's sense of social responsibility. Common Issues and Solutions Common Defects in the Production ProcessCommon defects in choke production processes include coil short circuits, core damage, and insulation layer failure. These issues not only affect product performance but may also pose safety hazards. Factors Affecting Choke PerformanceChoke performance is influenced by various factors, including material selection, production processes, and environmental conditions. Understanding these factors can help make targeted improvements during the production process. Solutions and Improvement MeasuresFor common issues, companies can adopt various solutions such as optimizing production processes, strengthening quality control, and regularly maintaining equipment to improve the overall quality of products. Future Development Trends Development and Application of New MaterialsWith technological advancements, the development of new materials will provide more possibilities for improving the performance of chokes. For example, the application of nanomaterials and composite materials may significantly enhance the magnetic properties and heat resistance of chokes. Application of Smart Manufacturing in Choke ProductionThe introduction of smart manufacturing technology will make choke production more efficient and flexible. Through big data analysis and artificial intelligence technology, real-time monitoring and optimization of the production process can be achieved. Impact of Market Demand Changes on Production ProcessesWith the continuous upgrading of electronic products, market demand for chokes is also changing. Production companies need to adjust production processes in a timely manner to adapt to market changes and customer needs. ConclusionAs an indispensable component in electronic devices, the optimization of choke production processes is of great significance for improving product performance and market competitiveness. By analyzing materials selection, production processes, key technologies, and common issues in depth, we can better understand the production processes of chokes and provide reference for the future development of the industry.In the future, with the development of new materials, the application of smart manufacturing technology, and changes in market demand, the production processes of chokes will continue to evolve, driving the continuous development of the electronics industry. References- Relevant books and journals- Industry standards and regulations- Latest research findings on production processesThrough the discussions above, we hope to provide valuable references for companies and technical personnel engaged in choke production, and contribute to the progress and development of the industry. Common Production Processes of Chokes IntroductionA choke is an important inductive component widely used in electronic devices, especially in power management, filtering, and signal processing. Its main function is to suppress high-frequency noise, smooth current fluctuations, and improve the stability and reliability of the circuit. With the continuous development of electronic technology, the performance requirements of chokes are also increasing, making the optimization of production processes particularly important.In this article, we will delve into the basic structure of chokes, production process flow, key technologies, common issues, and future development trends, in order to provide reference for practitioners in related industries. Basic Structure of Chokes Selection of Magnetic Core MaterialsThe core part of a choke is the magnetic core, and the choice of material directly affects the performance of the choke. Common magnetic core materials include ferrites, silicon steel sheets, and powdered iron cores. Ferrite materials have good high-frequency characteristics and are suitable for high-frequency applications; while silicon steel sheets perform well in low-frequency applications. Powdered iron cores are increasingly favored for their excellent magnetic properties and low losses. Design of Winding CoilsWinding coils are another important component of chokes, and their design needs to consider factors such as the number of turns, wire diameter, and winding method. Increasing the number of turns can increase the inductance value, but it will also increase the DC resistance of the coil, affecting efficiency. Therefore, a reasonable balance is needed in the design. Role of Enclosure and Insulation MaterialsThe enclosure not only protects the internal structure of the choke but also prevents external interference. Insulation materials ensure electrical isolation between the coil and the magnetic core, preventing short circuits and leakage. Common insulation materials include polyester film, epoxy resin, etc. Production Process Flow of Chokes 1. Material Preparation Types and Characteristics of Magnetic Core MaterialsBefore producing chokes, various materials need to be prepared. The choice of magnetic core material is crucial, as the permeability, losses, and temperature characteristics of different materials will affect the performance of the final product. Selection of Winding Coil MaterialsWinding coils typically use copper or aluminum wire, with copper wire being widely used due to its excellent conductivity. The choice of wire diameter needs to be determined based on design requirements and current magnitude. Preparation of Insulation MaterialsThe choice of insulation materials is equally important to ensure their heat resistance, voltage resistance, and insulation performance to meet the requirements of different working environments. 2. Processing of Magnetic Cores Cutting and Forming of Magnetic CoresThe processing of magnetic cores typically involves cutting and forming. Precision in cutting is necessary to facilitate subsequent assembly. Forming needs to be done according to design requirements to ensure the shape of the magnetic core meets standards. Surface Treatment of Magnetic CoresSurface treatment can improve the corrosion resistance and mechanical strength of magnetic cores. Common treatment methods include spraying and galvanizing. Heat Treatment Process of Magnetic CoresHeat treatment can improve the magnetic properties of magnetic cores and reduce losses. The heat treatment process varies for different materials and needs to be adjusted accordingly. 3. Winding of Coils Selection of Winding EquipmentCoil winding is typically done using automated equipment to improve production efficiency and consistency. The choice of equipment needs to consider the specifications of the coil and the scale of production. Setting of Winding Process ParametersDuring the winding process, process parameters such as winding speed, tension, and number of turns need to be accurately set to ensure the quality of the coil. Insulation Treatment of CoilsAfter winding is completed, the coil needs to undergo insulation treatment. Common methods include impregnation and coating with insulation materials to improve its insulation performance. 4. Assembly of Components Bonding of Magnetic Cores and CoilsDuring assembly, the coil needs to be tightly bonded to the magnetic core to ensure good electromagnetic coupling. Care should be taken to avoid damaging the insulation layer of the coil during bonding. Addition of Insulation LayerAfter assembly, an additional insulation layer is usually added to further enhance the electrical isolation performance. Installation of EnclosureFinally, the enclosure is installed to protect the internal components, and the material and design of the enclosure need to consider factors such as heat dissipation and protection. 5. Testing and Inspection Electrical Performance TestingAfter assembly, chokes need to undergo electrical performance testing, including inductance value, DC resistance, and withstand voltage, to ensure they meet design requirements. Mechanical Strength TestingMechanical strength testing primarily evaluates the durability of chokes during use, ensuring they can withstand external impacts and vibrations. Environmental Adaptability TestingEnvironmental adaptability testing includes high temperature, low temperature, humidity, etc., to ensure the stability and reliability of chokes under various environmental conditions. Key Technologies in Production Processes Application of Automation Technology in ProductionWith the advancement of technology, automation technology has been widely applied in choke production. Automated equipment not only improves production efficiency but also reduces errors from manual operations, ensuring product consistency and stability. Quality Control and ManagementQuality control is crucial during the production process. By establishing a sound quality management system and implementing full monitoring, defect rates can be effectively reduced, and product qualification rates can be improved. Use of Environmentally Friendly Materials and Sustainable DevelopmentWith the increasing environmental awareness, more and more companies are paying attention to environmental issues in the production process. The use of environmentally friendly materials and sustainable production processes not only helps protect the environment but also enhances the company's sense of social responsibility. Common Issues and Solutions Common Defects in the Production ProcessCommon defects in choke production processes include coil short circuits, core damage, and insulation layer failure. These issues not only affect product performance but may also pose safety hazards. Factors Affecting Choke PerformanceChoke performance is influenced by various factors, including material selection, production processes, and environmental conditions. Understanding these factors can help make targeted improvements during the production process. Solutions and Improvement MeasuresFor common issues, companies can adopt various solutions such as optimizing production processes, strengthening quality control, and regularly maintaining equipment to improve the overall quality of products. Future Development Trends Development and Application of New MaterialsWith technological advancements, the development of new materials will provide more possibilities for improving the performance of chokes. For example, the application of nanomaterials and composite materials may significantly enhance the magnetic properties and heat resistance of chokes. Application of Smart Manufacturing in Choke ProductionThe introduction of smart manufacturing technology will make choke production more efficient and flexible. Through big data analysis and artificial intelligence technology, real-time monitoring and optimization of the production process can be achieved. Impact of Market Demand Changes on Production ProcessesWith the continuous upgrading of electronic products, market demand for chokes is also changing. Production companies need to adjust production processes in a timely manner to adapt to market changes and customer needs. ConclusionAs an indispensable component in electronic devices, the optimization of choke production processes is of great significance for improving product performance and market competitiveness. By analyzing materials selection, production processes, key technologies, and common issues in depth, we can better understand the production processes of chokes and provide reference for the future development of the industry.In the future, with the development of new materials, the application of smart manufacturing technology, and changes in market demand, the production processes of chokes will continue to evolve, driving the continuous development of the electronics industry. References- Relevant books and journals- Industry standards and regulations- Latest research findings on production processesThrough the discussions above, we hope to provide valuable references for companies and technical personnel engaged in choke production, and contribute to the progress and development of the industry.

Analysis of Popular Coil Models Prices in Stock IntroductionCoils are essential components in electrical and electronic devices, widely used in transformers, inductors, motors, and other equipment. Their basic functions include storing electrical energy, converting voltage and current, and filtering. With the advancement of technology and the increasing demand for electrical equipment in various industries, the market demand for coils in stock is also continuously rising. This article will provide an in-depth analysis of the prices of popular coil models in stock, discussing their market status, price influencing factors, and future trends. 1. Basic Knowledge of Coils 1.1 Definition of CoilsA coil is an electrical component made of a conductive material (usually copper or aluminum) wound into a coil. Its basic structure includes conductors, insulation materials, and support structures. The function of a coil is mainly based on the principle of electromagnetic induction, which can generate a magnetic field when current passes through it, and induce a current when the magnetic field changes. Coils play a crucial role in electrical and electronic devices, especially in transformers and inductors. 1.2 Classification of CoilsCoils can be classified based on materials and applications:Based on materials:Copper coils: Widely used in high-performance electrical equipment due to their excellent conductivity and thermal conductivity.Aluminum coils: Relatively lightweight and cost-effective, suitable for applications sensitive to weight and cost.Based on applications:Transformer coils: Used for voltage conversion, widely applied in power systems.Inductor coils: Used for energy storage and filtering, commonly found in electronic devices. 2. Overview of Popular Coil Models 2.1 Common Coil ModelsThere are various coil models in the market, here are a few popular models:EFD series: These coils are typically used in switch-mode power supplies and transformers, with high efficiency and compact size.EE series: Widely used in power transformers, with good magnetic performance and low losses.R-core series: Preferred for their low noise and high efficiency, suitable for high-fidelity audio and high-frequency transformers. 2.2 Criteria for Choosing Coil ModelsWhen selecting the appropriate coil model, the following criteria need to be considered:Electrical parameters: Such as current, voltage, and frequency, to ensure the coil meets the operational requirements of the equipment.Physical dimensions and installation requirements: Choose the appropriate coil model based on the space constraints and installation method of the equipment. 3. Analysis of the Stock Coil Market 3.1 Current Market DemandCurrently, the demand for coils in the market is continuously increasing, especially in industries such as automotive, home appliances, and telecommunications. With the popularity of electric vehicles and smart homes, the demand for coils is also on the rise. For example, electric vehicles require a large number of high-performance coils for motors and charging equipment, while smart home devices require efficient power management systems. 3.2 Factors Affecting PricesThe fluctuation of coil prices is influenced by various factors:Fluctuation of raw material prices: The fluctuation of prices of raw materials such as copper and aluminum directly affects the production cost of coils, thereby impacting market prices.Production costs and technological advancements: With improvements in production processes and technological advancements, production costs may decrease, thereby affecting the market prices of coils. 4. Analysis of Prices of Popular Coil Models 4.1 Overview of Specific Model PricesHere is an overview of the prices of several popular coil models and their stock prices (prices are for reference, actual prices may vary due to market fluctuations):EFD series: Price range of $5-15 per unit, specific prices depend on specifications and manufacturers.EE series: Price range of $3-10 per unit, suitable for bulk purchases.R-core series: Price range of $10-25 per unit, higher priced due to its high performance. 4.2 Price Comparison and Market PositioningThere is a significant price difference between different brands of coils. For example, coils from well-known brands in the EFD series may have higher prices, but they also offer better performance and reliability. On the other hand, coils from lesser-known brands may have lower prices, but there may be differences in performance and quality. Therefore, industry practitioners need to consider the cost-effectiveness when choosing coils. 5. Future Market Trends 5.1 Impact of Technological Advancements on the Coil MarketWith the emergence of new materials and technologies, the performance and prices of coils will be affected. For example, coils using high-conductivity materials can improve efficiency and reduce energy consumption. Additionally, the trend towards smart and automated systems will drive the demand for high-performance coils, especially in the electric vehicle and smart home sectors. 5.2 Predicted Future Price TrendsBased on market demand and supply chain analysis, the prices of coils in the future may exhibit the following trends:Steady growth: With increasing demand, coil prices may gradually rise.Volatility: Fluctuations in raw material prices may lead to short-term price fluctuations of coils, industry practitioners need to closely monitor market dynamics. 6. ConclusionIn conclusion, the prices of popular coil models in stock are influenced by various factors, including market demand, raw material prices, and production costs. When selecting coils, industry practitioners should consider factors such as performance, price, and brand to ensure the selection of the most suitable product. In the future, with technological advancements and market changes, the coil market will continue to develop, and industry practitioners should maintain keen market insights to address potential challenges and opportunities. References- Industry Report: Analysis and Forecast of the Coil Market- Market Analysis Article: Future Trends of Electrical Components- Relevant Technical Literature: Application of New Materials in Electrical EquipmentThe above is a comprehensive analysis of the prices of popular coil models in stock, hoping to provide valuable references for industry practitioners. Analysis of Popular Coil Models Prices in Stock IntroductionCoils are essential components in electrical and electronic devices, widely used in transformers, inductors, motors, and other equipment. Their basic functions include storing electrical energy, converting voltage and current, and filtering. With the advancement of technology and the increasing demand for electrical equipment in various industries, the market demand for coils in stock is also continuously rising. This article will provide an in-depth analysis of the prices of popular coil models in stock, discussing their market status, price influencing factors, and future trends. 1. Basic Knowledge of Coils 1.1 Definition of CoilsA coil is an electrical component made of a conductive material (usually copper or aluminum) wound into a coil. Its basic structure includes conductors, insulation materials, and support structures. The function of a coil is mainly based on the principle of electromagnetic induction, which can generate a magnetic field when current passes through it, and induce a current when the magnetic field changes. Coils play a crucial role in electrical and electronic devices, especially in transformers and inductors. 1.2 Classification of CoilsCoils can be classified based on materials and applications:Based on materials:Copper coils: Widely used in high-performance electrical equipment due to their excellent conductivity and thermal conductivity.Aluminum coils: Relatively lightweight and cost-effective, suitable for applications sensitive to weight and cost.Based on applications:Transformer coils: Used for voltage conversion, widely applied in power systems.Inductor coils: Used for energy storage and filtering, commonly found in electronic devices. 2. Overview of Popular Coil Models 2.1 Common Coil ModelsThere are various coil models in the market, here are a few popular models:EFD series: These coils are typically used in switch-mode power supplies and transformers, with high efficiency and compact size.EE series: Widely used in power transformers, with good magnetic performance and low losses.R-core series: Preferred for their low noise and high efficiency, suitable for high-fidelity audio and high-frequency transformers. 2.2 Criteria for Choosing Coil ModelsWhen selecting the appropriate coil model, the following criteria need to be considered:Electrical parameters: Such as current, voltage, and frequency, to ensure the coil meets the operational requirements of the equipment.Physical dimensions and installation requirements: Choose the appropriate coil model based on the space constraints and installation method of the equipment. 3. Analysis of the Stock Coil Market 3.1 Current Market DemandCurrently, the demand for coils in the market is continuously increasing, especially in industries such as automotive, home appliances, and telecommunications. With the popularity of electric vehicles and smart homes, the demand for coils is also on the rise. For example, electric vehicles require a large number of high-performance coils for motors and charging equipment, while smart home devices require efficient power management systems. 3.2 Factors Affecting PricesThe fluctuation of coil prices is influenced by various factors:Fluctuation of raw material prices: The fluctuation of prices of raw materials such as copper and aluminum directly affects the production cost of coils, thereby impacting market prices.Production costs and technological advancements: With improvements in production processes and technological advancements, production costs may decrease, thereby affecting the market prices of coils. 4. Analysis of Prices of Popular Coil Models 4.1 Overview of Specific Model PricesHere is an overview of the prices of several popular coil models and their stock prices (prices are for reference, actual prices may vary due to market fluctuations):EFD series: Price range of $5-15 per unit, specific prices depend on specifications and manufacturers.EE series: Price range of $3-10 per unit, suitable for bulk purchases.R-core series: Price range of $10-25 per unit, higher priced due to its high performance. 4.2 Price Comparison and Market PositioningThere is a significant price difference between different brands of coils. For example, coils from well-known brands in the EFD series may have higher prices, but they also offer better performance and reliability. On the other hand, coils from lesser-known brands may have lower prices, but there may be differences in performance and quality. Therefore, industry practitioners need to consider the cost-effectiveness when choosing coils. 5. Future Market Trends 5.1 Impact of Technological Advancements on the Coil MarketWith the emergence of new materials and technologies, the performance and prices of coils will be affected. For example, coils using high-conductivity materials can improve efficiency and reduce energy consumption. Additionally, the trend towards smart and automated systems will drive the demand for high-performance coils, especially in the electric vehicle and smart home sectors. 5.2 Predicted Future Price TrendsBased on market demand and supply chain analysis, the prices of coils in the future may exhibit the following trends:Steady growth: With increasing demand, coil prices may gradually rise.Volatility: Fluctuations in raw material prices may lead to short-term price fluctuations of coils, industry practitioners need to closely monitor market dynamics. 6. ConclusionIn conclusion, the prices of popular coil models in stock are influenced by various factors, including market demand, raw material prices, and production costs. When selecting coils, industry practitioners should consider factors such as performance, price, and brand to ensure the selection of the most suitable product. In the future, with technological advancements and market changes, the coil market will continue to develop, and industry practitioners should maintain keen market insights to address potential challenges and opportunities. References- Industry Report: Analysis and Forecast of the Coil Market- Market Analysis Article: Future Trends of Electrical Components- Relevant Technical Literature: Application of New Materials in Electrical EquipmentThe above is a comprehensive analysis of the prices of popular coil models in stock, hoping to provide valuable references for industry practitioners.

Understanding Reactive Power Compensation Capacitors

I. Introduction

In the realm of electrical engineering, the concept of reactive power is often overlooked, yet it plays a crucial role in the efficiency and stability of electrical systems. Reactive power, unlike active power, does not perform any useful work but is essential for maintaining voltage levels that allow active power to flow. This article aims to demystify reactive power compensation capacitors, exploring their significance, functionality, and applications in various sectors.

II. Basics of Reactive Power

To fully grasp the importance of reactive power compensation capacitors, it is essential to understand the different types of power in electrical systems:

A. Explanation of Power Types

1. **Active Power (Real Power)**: This is the power that performs actual work in an electrical system, measured in watts (W). It powers devices like lights, heaters, and motors.

2. **Reactive Power**: Measured in volt-amperes reactive (VAR), reactive power is the power that oscillates between the source and the load. It is necessary for creating magnetic fields in inductive loads, such as motors and transformers.

3. **Apparent Power**: This is the combination of active and reactive power, measured in volt-amperes (VA). It represents the total power flowing in the system.

B. The Role of Inductive and Capacitive Loads

Electrical systems consist of both inductive and capacitive loads:

1. **Inductive Loads**: Devices like motors and transformers draw reactive power, which can lead to a lagging power factor. This means that the current lags behind the voltage, causing inefficiencies.

2. **Capacitive Loads**: Capacitors can provide reactive power, counteracting the effects of inductive loads and improving the power factor.

C. Power Factor and Its Significance

The power factor is the ratio of active power to apparent power and is a measure of how effectively electrical power is being converted into useful work. A power factor of 1 (or 100%) indicates that all the power is being used effectively. A low power factor can lead to increased energy costs and reduced system capacity.

III. What are Reactive Power Compensation Capacitors?

A. Definition and Function

Reactive power compensation capacitors are devices used to improve the power factor in electrical systems. By providing reactive power locally, they reduce the demand for reactive power from the grid, leading to improved efficiency and reduced energy costs.

B. Types of Capacitors Used for Compensation

1. **Fixed Capacitors**: These are permanently installed capacitors that provide a constant amount of reactive power. They are typically used in applications where the load is stable.

2. **Automatic Capacitors**: These capacitors adjust their output based on the load conditions. They are equipped with control systems that monitor the power factor and switch on or off as needed.

C. How Capacitors Provide Reactive Power

Capacitors store electrical energy in an electric field and release it when needed. When connected to an inductive load, they can supply the reactive power required, thus improving the overall power factor of the system.

IV. The Need for Reactive Power Compensation

A. Consequences of Low Power Factor

A low power factor can have several negative consequences:

1. **Increased Energy Costs**: Utilities often charge higher rates for customers with low power factors, as they must generate more reactive power to meet demand.

2. **Reduced System Capacity**: Low power factor can lead to overloading of transformers and conductors, reducing the overall capacity of the electrical system.

3. **Potential Equipment Damage**: Excessive reactive power can cause overheating and damage to electrical equipment, leading to costly repairs and downtime.

B. Benefits of Reactive Power Compensation

1. **Improved Power Factor**: By providing reactive power locally, capacitors help to improve the power factor, reducing energy costs.

2. **Enhanced System Efficiency**: Improved power factor leads to more efficient use of electrical power, reducing losses in transmission and distribution.

3. **Reduced Losses in Transmission and Distribution**: With a better power factor, the current flowing through the system is reduced, leading to lower losses in the form of heat.

V. Applications of Reactive Power Compensation Capacitors

A. Industrial Applications

1. **Manufacturing Plants**: Large machinery and motors in manufacturing facilities often require reactive power compensation to maintain efficiency and reduce costs.

2. **Large Motors and Machinery**: Industries with heavy machinery benefit significantly from reactive power compensation, as it helps to stabilize voltage levels and improve performance.

B. Commercial Applications

1. **Office Buildings**: Many office buildings use reactive power compensation to improve energy efficiency and reduce utility costs.

2. **Retail Spaces**: Retailers can benefit from improved power factor, leading to lower energy bills and enhanced lighting performance.

C. Utility Applications

1. **Grid Stability**: Utilities use reactive power compensation to maintain grid stability and ensure reliable power delivery.

2. **Voltage Regulation**: Capacitors help regulate voltage levels in the grid, preventing fluctuations that can affect the performance of electrical devices.

VI. Design and Implementation of Reactive Power Compensation

A. Assessing the Need for Compensation

1. **Power Factor Analysis**: Conducting a power factor analysis helps identify the need for reactive power compensation.

2. **Load Characteristics**: Understanding the load characteristics is crucial for determining the appropriate type and size of capacitors.

B. Sizing Capacitors for Specific Applications

Proper sizing of capacitors is essential to ensure effective compensation without overcompensation, which can lead to other issues.

C. Installation Considerations

1. **Location and Placement**: The placement of capacitors within the electrical system can significantly impact their effectiveness.

2. **Safety and Compliance**: Ensuring compliance with safety standards and regulations is critical during installation.

D. Maintenance and Monitoring

Regular maintenance and monitoring of reactive power compensation systems are necessary to ensure optimal performance and longevity.

VII. Challenges and Considerations

A. Overcompensation and Its Effects

Overcompensation can lead to a leading power factor, which can cause voltage rise and potential damage to equipment.

B. Harmonics and Their Impact on Capacitor Performance

Harmonics generated by non-linear loads can affect the performance of capacitors, leading to overheating and reduced lifespan.

C. Environmental Considerations

The environmental impact of capacitor manufacturing and disposal should be considered in the design and implementation process.

D. Regulatory and Compliance Issues

Staying compliant with industry regulations and standards is essential for the successful operation of reactive power compensation systems.

VIII. Future Trends in Reactive Power Compensation

A. Technological Advancements

1. **Smart Capacitors and Automated Systems**: The integration of smart technology allows for real-time monitoring and adjustment of reactive power compensation.

2. **Integration with Renewable Energy Sources**: As renewable energy sources become more prevalent, reactive power compensation will play a vital role in maintaining grid stability.

B. The Role of Energy Storage Systems

Energy storage systems can complement reactive power compensation by providing additional support during peak demand periods.

C. Evolving Regulations and Standards

As the energy landscape evolves, so too will the regulations and standards governing reactive power compensation.

IX. Conclusion

Reactive power compensation capacitors are essential components in modern electrical systems, playing a critical role in improving power factor, enhancing efficiency, and reducing energy costs. As technology advances and the demand for efficient energy use grows, understanding and implementing reactive power compensation will become increasingly important. We encourage readers to explore this field further, as the implications of reactive power compensation extend far beyond individual systems, impacting the broader energy landscape.

X. References

For those interested in delving deeper into the topic of reactive power compensation, consider exploring the following resources:

- IEEE Standards on Power Quality

- "Power System Analysis" by John J. Grainger and William D. Stevenson

- Industry publications on energy efficiency and power factor correction

By understanding the principles and applications of reactive power compensation capacitors, individuals and organizations can make informed decisions that lead to more efficient and reliable electrical systems.

Latest Inductor Symbol Specifications

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various applications, including filtering, energy storage, and signal processing. As the complexity of electronic designs increases, the importance of clear and standardized symbols for inductors in electronic schematics cannot be overstated. This article aims to provide an overview of the latest specifications for inductor symbols, ensuring that engineers and designers can effectively communicate their designs.

II. Historical Context of Inductor Symbols

The representation of inductors in electronic schematics has evolved significantly over the years. In the early days of electronics, symbols were often inconsistent and varied widely between different manufacturers and design practices. This lack of standardization led to confusion and misinterpretation of schematics.

Historically, organizations such as the IEEE (Institute of Electrical and Electronics Engineers) and the IEC (International Electrotechnical Commission) have worked to establish standards for electronic symbols, including those for inductors. These standards have undergone several revisions to accommodate advancements in technology and changes in design practices. The transition to modern specifications has aimed to create a more uniform approach to symbol representation, enhancing clarity and reducing errors in electronic design.

III. Current Standards for Inductor Symbols

A. Overview of Relevant Standards Organizations

Several organizations play a pivotal role in establishing and maintaining standards for electronic symbols:

1. **IEEE (Institute of Electrical and Electronics Engineers)**: The IEEE develops standards that are widely adopted in the electronics industry, including those for schematic symbols.

2. **IEC (International Electrotechnical Commission)**: The IEC provides international standards for electrical and electronic devices, including symbol specifications.

3. **ANSI (American National Standards Institute)**: ANSI oversees the development of voluntary consensus standards for various industries, including electronics.

B. Key Specifications for Inductor Symbols

The latest specifications for inductor symbols focus on several key aspects:

1. **Shape and Design**: The standard inductor symbol typically consists of a series of loops or coils, representing the wire winding. The design should be simple yet recognizable, ensuring that it can be easily interpreted by anyone reading the schematic.

2. **Size and Scale**: Inductor symbols should be proportionate to other components in the schematic. Consistency in size helps maintain clarity and readability, especially in complex designs.

3. **Color Coding and Labeling**: While color coding is not universally standardized, some practices suggest using specific colors to indicate different types of inductors or their characteristics. Clear labeling, including values and specifications, is essential for effective communication.

IV. Types of Inductor Symbols

A. Basic Inductor Symbol

The basic inductor symbol is a simple representation consisting of a series of curved lines or loops. This symbol is widely recognized and used in most electronic schematics. It is essential for representing standard inductors in various applications.

1. Description and Usage

The basic inductor symbol is used to denote inductors in circuits, indicating their presence and function. It is crucial for circuit analysis and design, as it helps engineers understand the behavior of the circuit.

2. Variations in Representation

While the basic symbol is widely accepted, variations may exist based on regional standards or specific design requirements. Engineers should be aware of these variations to ensure clarity in their designs.

B. Specialized Inductor Symbols

In addition to the basic inductor symbol, there are specialized symbols for different types of inductors:

1. **Variable Inductors**: These symbols often include an arrow or a specific notation to indicate that the inductance can be adjusted.

2. **Coupled Inductors**: Coupled inductors, which consist of two or more inductors magnetically linked, may be represented with additional lines or dots to indicate their coupling.

3. **Ferrite Core Inductors**: Symbols for ferrite core inductors may include annotations or markings to specify the core material, which is crucial for understanding the inductor's performance characteristics.

C. Inductor with Core Material Specifications

Inductor symbols can also indicate core material types, such as air or ferrite. This specification is important because the core material significantly affects the inductor's performance, including its inductance value, saturation current, and frequency response.

V. Best Practices for Using Inductor Symbols

A. Consistency in Symbol Usage Across Schematics

To avoid confusion, it is essential to maintain consistency in the use of inductor symbols across different schematics. This practice ensures that anyone reading the design can quickly understand the components and their functions.

B. Importance of Clear Labeling and Annotations

Clear labeling and annotations are vital for effective communication in electronic schematics. Engineers should include values, specifications, and any relevant notes to provide context for the inductor's role in the circuit.

C. Common Mistakes to Avoid When Using Inductor Symbols

Common mistakes include using incorrect symbols, failing to label components adequately, and not adhering to established standards. Engineers should be vigilant in avoiding these pitfalls to ensure the accuracy and clarity of their designs.

VI. Software and Tools for Inductor Symbol Implementation

A. Overview of Popular Electronic Design Automation (EDA) Tools

Several electronic design automation (EDA) tools facilitate the implementation of inductor symbols in schematics. Some of the most popular tools include:

1. **Altium Designer**: Known for its advanced features and user-friendly interface, Altium Designer supports the latest inductor symbol specifications and allows for easy integration into designs.

2. **Eagle**: A widely used tool for PCB design, Eagle provides a library of standard symbols, including those for inductors, making it easy for engineers to create accurate schematics.

3. **KiCad**: An open-source EDA tool, KiCad offers a comprehensive library of symbols and components, including inductor symbols, allowing for flexibility in design.

B. Features that Support the Latest Inductor Symbol Specifications

These EDA tools often include features such as symbol libraries, design rule checks, and the ability to customize symbols to meet specific design requirements. Utilizing these features can enhance the accuracy and efficiency of the design process.

C. Tips for Integrating Symbols into Designs

When integrating inductor symbols into designs, engineers should ensure that they are using the correct symbols from the library, maintain consistency in size and labeling, and double-check for any potential errors before finalizing the schematic.

VII. Future Trends in Inductor Symbol Specifications

A. Impact of Emerging Technologies (e.g., IoT, AI) on Inductor Design

As technology continues to evolve, the design and application of inductors are also changing. Emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are driving the need for more compact and efficient inductors, which may influence future symbol specifications.

B. Potential Changes in Standards and Practices

As the industry adapts to new technologies, standards organizations may revise existing specifications to accommodate new types of inductors and their applications. Staying informed about these changes is crucial for engineers and designers.

C. The Role of Community Feedback in Evolving Specifications

Community feedback plays a vital role in the evolution of inductor symbol specifications. Engineers and designers are encouraged to share their experiences and suggestions with standards organizations to help shape future guidelines.

VIII. Conclusion

Adhering to the latest inductor symbol specifications is essential for effective communication in electronic design. By understanding the historical context, current standards, and best practices, engineers can create clear and accurate schematics that facilitate collaboration and reduce errors. As technology continues to advance, staying updated on the latest specifications will be crucial for the future of inductor symbols in electronic design.

IX. References

1. IEEE Standards Association. (n.d.). Retrieved from [IEEE Standards](https://standards.ieee.org/)

2. International Electrotechnical Commission. (n.d.). Retrieved from [IEC Standards](https://www.iec.ch/)

3. American National Standards Institute. (n.d.). Retrieved from [ANSI Standards](https://www.ansi.org/)

4. Altium Designer. (n.d.). Retrieved from [Altium](https://www.altium.com/)

5. Eagle PCB Design Software. (n.d.). Retrieved from [Eagle](https://www.autodesk.com/products/eagle/overview)

6. KiCad EDA. (n.d.). Retrieved from [KiCad](https://www.kicad.org/)

This comprehensive overview of the latest inductor symbol specifications provides valuable insights for engineers and designers, ensuring that they can effectively communicate their designs and stay ahead in the rapidly evolving field of electronics.

What is the Market Prospect of Inductors?

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and voltage regulation. As the backbone of many electronic devices, inductors are essential in ensuring the smooth operation of everything from consumer electronics to industrial machinery. This blog post explores the market prospects of inductors, examining historical trends, types, applications, market drivers, challenges, regional analyses, and future innovations.

II. Historical Context

The technology behind inductors has evolved significantly since their inception. The first inductors were simple coils of wire, but advancements in materials and manufacturing processes have led to the development of various types of inductors, including air-core, iron-core, and ferrite-core inductors. Key milestones in the inductor market include the introduction of ferrite materials in the 1950s, which allowed for smaller and more efficient inductors, and the rise of surface-mount technology (SMT) in the 1980s, which revolutionized the way inductors are integrated into electronic circuits.

Historically, the inductor market has experienced steady growth, driven by the increasing demand for electronic devices. The proliferation of consumer electronics in the late 20th century and the subsequent rise of mobile technology have significantly contributed to this growth. As we move into the 21st century, the market continues to expand, fueled by advancements in technology and the growing complexity of electronic systems.

III. Types of Inductors

Inductors come in various types, each suited for specific applications:

A. Air-core Inductors

These inductors do not use a magnetic core, making them lightweight and suitable for high-frequency applications. They are often used in radio frequency (RF) circuits.

B. Iron-core Inductors

Iron-core inductors utilize an iron core to enhance inductance. They are commonly used in power applications due to their ability to handle higher currents.

C. Ferrite-core Inductors

Ferrite-core inductors are popular in modern electronics due to their high efficiency and compact size. They are widely used in power supplies and filtering applications.

D. Other Specialized Inductors

Specialized inductors, such as toroidal and multilayer inductors, offer unique benefits. Toroidal inductors have a doughnut shape that minimizes electromagnetic interference, while multilayer inductors are used in compact devices due to their small footprint.

E. Comparison of Different Types

Each type of inductor has its advantages and disadvantages, making them suitable for different applications. For instance, air-core inductors are ideal for high-frequency applications, while ferrite-core inductors are preferred for power supply circuits.

IV. Applications of Inductors

Inductors find applications across various industries, including:

A. Consumer Electronics

Inductors are integral to smartphones, tablets, laptops, and desktops, where they help manage power supply and signal integrity.

B. Automotive Industry

With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), inductors are increasingly used in automotive applications to manage power and improve efficiency.

C. Industrial Applications

In industrial settings, inductors are used in power supplies and automation systems, where they help regulate voltage and current.

D. Telecommunications

Inductors play a vital role in networking equipment and 5G technology, where they are used for filtering and signal processing.

E. Renewable Energy Systems

Inductors are essential in renewable energy applications, such as wind and solar power systems, where they help manage energy storage and conversion.

V. Market Drivers

Several factors are driving the growth of the inductor market:

A. Growing Demand for Consumer Electronics

The increasing demand for smartphones, tablets, and other electronic devices is a significant driver of the inductor market. As technology advances, the need for more efficient and compact inductors continues to rise.

B. Rise of Electric Vehicles and Renewable Energy

The shift towards electric vehicles and renewable energy sources is creating new opportunities for inductors. As these industries grow, the demand for inductors that can handle higher power levels and improve efficiency will increase.

C. Advancements in Technology

Technological advancements, such as miniaturization and improved efficiency, are driving the development of new inductor designs. Manufacturers are continually innovating to meet the demands of modern electronic systems.

D. Increasing Complexity of Electronic Systems

As electronic systems become more complex, the need for reliable and efficient inductors grows. This complexity drives demand for specialized inductors that can meet specific performance requirements.

VI. Market Challenges

Despite the positive outlook, the inductor market faces several challenges:

A. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, leading to shortages of raw materials and components. These disruptions can impact the availability and pricing of inductors.

B. Competition from Alternative Technologies

Inductors face competition from alternative technologies, such as capacitors and transformers, which may offer similar functionalities in certain applications.

C. Regulatory Challenges and Environmental Concerns

As environmental regulations become stricter, manufacturers must adapt their processes to comply with new standards. This can increase production costs and impact profitability.

D. Price Volatility of Raw Materials

The prices of raw materials used in inductor manufacturing can be volatile, affecting production costs and pricing strategies.

VII. Regional Market Analysis

A. North America

The North American inductor market is characterized by a strong demand for consumer electronics and automotive applications. Key players in the region are focusing on innovation and product development to maintain a competitive edge.

B. Europe

In Europe, market trends are influenced by consumer preferences for energy-efficient products and regulatory requirements. The region is home to several leading manufacturers and is witnessing growth in the automotive and renewable energy sectors.

C. Asia-Pacific

The Asia-Pacific region is experiencing rapid industrialization and urbanization, leading to increased demand for inductors. Major manufacturing hubs in countries like China, Japan, and South Korea are driving market growth.

D. Latin America and Middle East & Africa

Emerging markets in Latin America and the Middle East & Africa present growth opportunities for the inductor market. As these regions develop their infrastructure and technology, the demand for inductors is expected to rise.

VIII. Future Trends and Innovations

The future of the inductor market is poised for exciting developments:

A. Technological Advancements in Inductor Design

Innovations in materials and manufacturing processes will lead to the development of more efficient and compact inductors, enhancing their performance in various applications.

B. Integration with Other Components

The trend towards integrating inductors with other components, such as capacitors and resistors, will create more compact and efficient electronic systems.

C. Smart Inductors and IoT Applications

The rise of the Internet of Things (IoT) is driving the development of smart inductors that can communicate and adapt to changing conditions, improving overall system performance.

D. Sustainability and Eco-Friendly Designs

As sustainability becomes a priority, manufacturers are focusing on eco-friendly designs and materials, reducing the environmental impact of inductor production.

IX. Conclusion

The market prospects for inductors are promising, driven by the growing demand for consumer electronics, the rise of electric vehicles, and advancements in technology. While challenges such as supply chain disruptions and competition from alternative technologies exist, the overall outlook remains positive. Stakeholders in the inductor market should focus on innovation, sustainability, and adapting to changing market dynamics to capitalize on the opportunities ahead.

X. References

1. Academic journals on electronics and materials science.

2. Industry reports from market research firms.

3. Market analysis publications from reputable sources.

4. Relevant websites and articles discussing inductor technology and market trends.

In conclusion, the inductor market is at a pivotal point, with numerous opportunities for growth and innovation. As technology continues to evolve, inductors will remain a vital component in the electronics industry, shaping the future of various applications.

When Will the Functions of the New Inductor Be Released?

I. Introduction

Inductors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. As technology advances, the demand for more efficient and versatile inductors has grown, prompting researchers and manufacturers to explore new functions and designs. This article aims to delve into the anticipated release of new inductor functions, examining their potential impact on various industries and the timeline for their availability.

II. Background on Inductors

A. Overview of Inductors and Their Basic Principles

Inductors are passive electrical components that store energy in a magnetic field when electrical current flows through them. The basic principle of inductance is rooted in Faraday's law of electromagnetic induction, which states that a change in magnetic flux can induce an electromotive force (EMF) in a conductor. Inductors are characterized by their inductance value, measured in henries (H), which indicates their ability to store energy.

There are several types of inductors, including air-core, iron-core, and toroidal inductors. Air-core inductors are lightweight and have low losses, making them suitable for high-frequency applications. Iron-core inductors, on the other hand, provide higher inductance values and are often used in power applications. Toroidal inductors, with their doughnut-shaped design, minimize electromagnetic interference and are favored in sensitive electronic circuits.

B. Historical Development of Inductors

The evolution of inductor technology has been marked by significant milestones. Early inductors were simple coils of wire, but advancements in materials and design have led to more efficient and compact versions. The introduction of ferrite materials in the mid-20th century allowed for higher inductance values in smaller packages, paving the way for modern applications in telecommunications and power electronics.

III. Current State of Inductor Technology

A. Overview of Existing Inductor Functions

Today, inductors are widely used in various applications, including power supplies, radio frequency (RF) circuits, and audio equipment. They serve essential functions such as filtering out unwanted signals, smoothing voltage fluctuations, and storing energy for later use. However, current inductor technology has its limitations, including size constraints, energy losses, and performance degradation at high frequencies.

B. Recent Advancements in Inductor Design